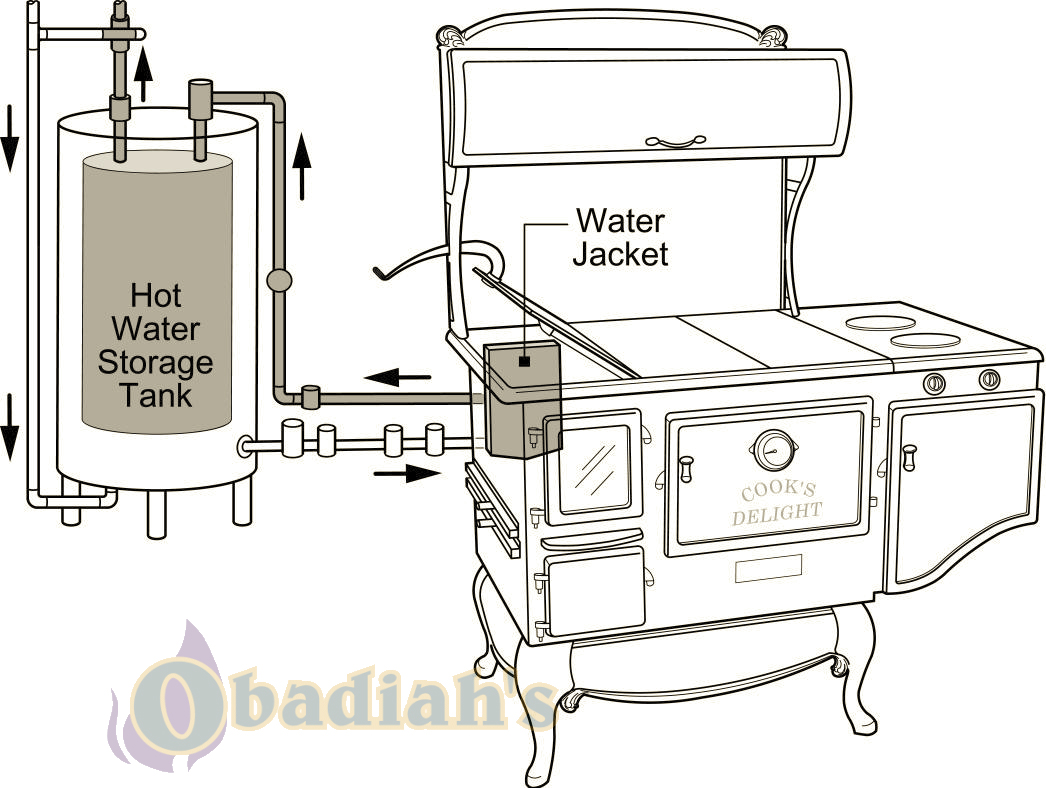

I've been trying to get the plumber to come out to my house just to give me an estimate and schedule a date for work to begin for my cook stove/range boiler. I'm starting to think they don't want the work, so perhaps it's time to learn how to solder pipes. I've been watching some videos and I think tomorrow I'll stop in the store for some wire brushes and try to practice on the stuff left over from previous repairs.

Any advice from folks who have worked with this stuff before? I'm also looking to install an electric on demand water heater as a backup since our current setup is really old. The whole plumbing situation in the utility room is terrible. I'm also going to try and tie in the rooftop solar water heater. There is an existing 110 pump that is very quiet I'd like to continue using. I'd like the pump to turn off when the water in the tank reaches 120dF or something like that. Is this where an aquastat would be used with the pump? There are currently sensors and a special panel to control the current system, but the electro-magnetic valves used for freeze protection (the system was designed to be used in the winter for some reason) are ridiculously loud. All of this stuff is from the 70's and basically unused, due to the super loud valves I'm sure. There are some leaks where the old manual valves are connected to the hot water tank plumbing, but I'm getting rid of all of that. Hopefully some of the copper pipe can be saved, but who knows.

Any advice from folks who have worked with this stuff before? I'm also looking to install an electric on demand water heater as a backup since our current setup is really old. The whole plumbing situation in the utility room is terrible. I'm also going to try and tie in the rooftop solar water heater. There is an existing 110 pump that is very quiet I'd like to continue using. I'd like the pump to turn off when the water in the tank reaches 120dF or something like that. Is this where an aquastat would be used with the pump? There are currently sensors and a special panel to control the current system, but the electro-magnetic valves used for freeze protection (the system was designed to be used in the winter for some reason) are ridiculously loud. All of this stuff is from the 70's and basically unused, due to the super loud valves I'm sure. There are some leaks where the old manual valves are connected to the hot water tank plumbing, but I'm getting rid of all of that. Hopefully some of the copper pipe can be saved, but who knows.

![[Hearth.com] Plumbing](/talk/data/attachments/247/247807-6f10f9540737f8d287aa1b29a7ee8d67.jpg?hash=rDvdctypwo)

![[Hearth.com] Plumbing](/talk/data/attachments/247/247808-0287cc3e3c42ef15b60149a11bb4b009.jpg?hash=npR8R4E6CK)

![[Hearth.com] Plumbing](/talk/data/attachments/247/247813-368b1b8f77b9a8337d94f167d49f7845.jpg?hash=Locl0u8qkB)

![[Hearth.com] Plumbing [Hearth.com] Plumbing](https://www.hearth.com/talk/data/attachments/247/247848-3ed3ed54ee85070e79ce59d2e4a3016b.jpg?hash=AIa0Ga14ED)

![[Hearth.com] Plumbing [Hearth.com] Plumbing](https://www.hearth.com/talk/data/attachments/247/247849-6b289ffa476e474f8a6d9c37a0801f6c.jpg?hash=3PLOQfYIly)

![[Hearth.com] Plumbing [Hearth.com] Plumbing](https://www.hearth.com/talk/data/attachments/247/247850-3cd77963288ffc6a385b8a6b8b182fc6.jpg?hash=024xFly1z6)

![[Hearth.com] Plumbing [Hearth.com] Plumbing](https://www.hearth.com/talk/data/attachments/247/247919-ddd93010522ae6b7747a431042e62d79.jpg?hash=zZS7RGtrf5)

![[Hearth.com] Plumbing [Hearth.com] Plumbing](https://www.hearth.com/talk/data/attachments/247/247920-52abcdee31f1740254ff0f4933f133fa.jpg?hash=liGxTIlvD3)

![[Hearth.com] Plumbing [Hearth.com] Plumbing](https://www.hearth.com/talk/data/attachments/247/247921-4b316c4c0577c0a6446c25bf741ee3a5.jpg?hash=Se_Rk1M2EV)