Its fully compliant to integrating mass and tested and listed to be compatible with thermal mass. Details on how to do so are in the owners manual. Integrating a thermal mass bench is possible, it has been done before by several of our previous customers, and it can make the heater more efficient. As a stand alone unit, the heater is ideal as a pellet stove, and heats 2,000 square feet quire comfortably. A lot of our customers live in environments that are effectively devoid of sufficient biomass, so they import fuel pellets, or are physically unable to chop, stack, and season wood, so they use fuel pellets. This stove is not for everyone. It is, effectively, a pellet stove that does not need electricity, that does not lock you into pellets in that you can burn wood, so the heater is not entirely useless if fuel pellet supplie chains are completely disrupted, and is more efficient than any other gravity fed pellet stove on the market by a long shot. Attached below is a photograph of our previous Gen 1 heater integrated into thermal mass, making it into a true Rocket Mass Heater and a form of masonry heater.

I'm well aware that multiple oxygen atoms need to attach to the various volatile organic compounds to fully burn. We are talking about pareto efficiency here, X amount of combustibles, and in an perfect model, all possible oxides that could form, would form. This would be 100% efficiency. For example, methane is 1 carbon atom and 4 hydrogen atoms. The stoichiometric ratio assuming pure oxygen would be 4 oxygen atoms to one methane molecule. Two for the carbon, to form Co2, and another 2 for the hydrogen atoms, to form water. Of course, wood being a less than ideal fuel containing literally thousands of complex proteins, carbohydrates, cellulose, bio-tar, water moisture, various carcinogens, minerals including non-combustible minerals, and a whole slough of combustion and thermal by-products, coupled with atmospheric air which itself is far from pure, and achieving optimal combustion efficiency can be rather difficult. That we have achieved 0.38 grams per hour of solid particulate emissions, and average less than 10 parts per million of carbon monoxide at any given time, is acceptable to me, given that most natural gas forced air furnaces average approximately 20 parts per million of carbon monoxide.

The EPA updates their approval listing periodically. Come the next update cycle we should be on their public ledger. Attached below are the test results from the EPA lab. We have as far as I can tell and am aware of, the cleanest burning non-catalytic non electric burning heater, and the #3 overall lowest solid particulate emissions and an exceptionally low CO emissions. This is independent EPA certified lab testing. They used the 99.5% combustion efficiency. This was not a figure I derived using my own equipment or practices, as we only have an inexpensive gas flue analyzer available and thus use CO emissions an an analogy to optimize for a full dilution tunnel test as our small business can not afford an in house dilution tunnel. The higher heating value could be better, I will admit, but our exhaust gas temperatures are still fairly low when compared to a wood stove, albeit higher than an electrically fed pellet stove, as we must use some of the heater to induce draft up the chimney. We do have an identical HHV to the wiseway stove, within the margin of error, and are much cleaner burning at less than half the average weighted emissions. The HHV is also better than many pellet stove's on the market, falling in at about average for HHV efficiency. Which is actually fairly good when you consider than we dont use any algorithmic control boards, sensors, regulators, fans, augers to control feed, draft inducers, automatic igniters, heat exchangers, etc. and we can also burn wood when integrated as a mass/masonry heater, so we had to engineer and optimize the heater to burn cleanly, efficiency, and reliably with two very different fuels.

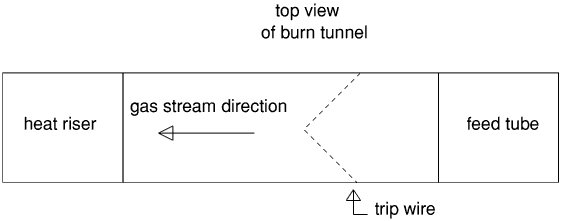

As far as backdrafting up the pellet feed tube, that was thoroughly tested and underwritten by Guardian Firetesting Labs and passed all their safety requirements outlined in UL and ASTM standards, which includes deliberately trying to force a jam, bridge, or blockade, and trying to induce a backdraft. The testing engineers were unable to force a backdraft, jam, or burn-back, despite deliberately attempting to induce those conditions. This design involved 7 years of active and expensive research and development which included materials science, metallurgy, computation fluid dynamic modelling, tested the coefficient of friction of various materials, and long term longevity testing, to achieve this threshold of reliability. Rheological and fluid modelling the flow of sand is notoriously difficult, and fuel pellets proved to be even more complicated. This was actually one of the main sticking problems when we first started development 7 years ago, and we thoroughly designed and optimized the feed system to completely obviate that previously systemic problem.

As far as cost, yes, it is expensive. We are also backordered through June and thus had to raise prices to prevent the backorder log from extending past an entire year as it did in Autumn of last year. Again, this heater is not for everyone. Its a pellet stove that can also burn wood, and is the only rocket heater that is listed to UL standards and building code compliant for thermal mass integration, which means everyone can now legally install a true rocket mass heater if they want a rocket mass heater in their home. Rocket mass heaters aren't for everyone, but there was a gap in the market as they work for many people, and for many people a rocket mass heater does work well with their lifestyle, so we developed a duel use heater that fits two mission profiles very well, gravity fed pellet stoves and building code compliant rocket mass heaters, with one product. It is also a pellet stove with a cooktop plate, which many (but not all) pellet stove's lack.

At the end of the day, we're not a huge company. Its just my father and I applying our engineering and fabrication skills to create value and bring more home and building heating options to people. We aren't the best at every mission profile, what we make isn't for everyone, but its worth considering for some people with specific desires or needs. It looks the way it does and is designed the way it is because we can only use the tools and machines available to us. We do not have fancy ornate cast iron pieces, or similar fancy hinged doors with ceramic fireglass, is because we do not have a 5 million dollar induction melting furnace and hydraulic sand pattern molding press to make heaters out of castings. We have a small welder, a plasma cutter, a small horizontal band saw, a small sheet metal brake, a small air compressor, and an old bridgeport milling machine. Thus we build what we can with the tools we have given what we have available to us. Maybe someday in the far flung future we will have a 5 million dollar induction furnace to make heaters out of recycled scrap iron, but that day is a long ways out. In the meantime, we have to weld them, thus they wont be winning any beauty pageants anytime soon. What I can tell is is that they are robust, American made heaters built and engineered to do their job with the unfaltering, unyielding, relentless reliability for decades at a time as used to be expected of all American manufactured products in a not so exceptionally bygone era, as was common of American industry. I took my personal job in engineering these heaters very seriously, as the designer I considered it my full obligation and duty to design these heaters to never fail, as lives are on the line, a single failure can lead to death in more than a few ways. I have done everything in my power and full scope of ability to ensure that does not happen, that the owners will stay warm, and that the heater will not clog, jam, or fail, or deteriorate via planned obsolescence (my personal arch nemesis, of which there is no other pattern of modernity I loathe more intensely).

Thank you all for the genuine questions, concerns, and wonderful comments. If there is anything else I can assists with or answer I would be elated to do so.

View attachment 293834

![[Hearth.com] UL listed pellet rocket mass heater [Hearth.com] UL listed pellet rocket mass heater](https://www.hearth.com/talk/data/attachments/293/293861-c1e3bd5754e231c2d6ce126ecc10d3b6.jpg?hash=DINfFOiXRo)