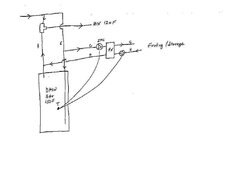

Not quite ghost flow, but looking for a solution. I'm using a plate hx to charge a DHW tank, plumbed as shown. The DHW side circ is a 15-58 IFC. What's happening is that when there is DHW demand and the circs are not "on," I'm getting an unwanted cold water flow through the domestic side of the hx which is letting cold water into the hot water supply from the DHW heater, thus cooling down the hot water supply output. I assume that the positive pressure on the cold side of the hx combined with the negative pressure on the hot side of the hx is sufficient to overcome the IFC and allow the flow. I thought about adding a spring check valve but am concerned about the amount of head it would add that would reduce the flow through the hx when the circs are "on." Also thought about adding a zone valve to block flow except when the circs are "on."

Other ideas:

1) input to the hx from the mix line and output to the cold water supply to the DHW heater? This might also allow flow through the hx, but at least that flow would be at the mix temp, not at the 50F cold water supply temp, and would be back into the tank and not into the hot water supply.

2) ?

Thanks.

Other ideas:

1) input to the hx from the mix line and output to the cold water supply to the DHW heater? This might also allow flow through the hx, but at least that flow would be at the mix temp, not at the 50F cold water supply temp, and would be back into the tank and not into the hot water supply.

2) ?

Thanks.