Hi,

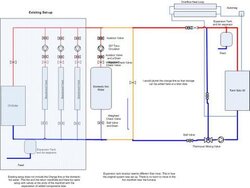

It has taken me 2 years to get around to installing this thing. It's time to get it done. I have been reading posts and doing my homework on and off for too long. I have been playing around with so many options as far as connecting it to my existing system that I just could not decide on the best approach. In the end I think the attached is how I plan to go about it. Can anyone give me feedback on this? Am I making any terrible mistakes? I am trying to make use of as much as possible with what I already have in place. Given that I don't have time to tear everything apart and start from scratch.

I don't currently have storage but would like to plan it in to add later if possible.

Comments?

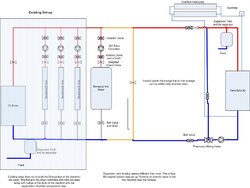

It has taken me 2 years to get around to installing this thing. It's time to get it done. I have been reading posts and doing my homework on and off for too long. I have been playing around with so many options as far as connecting it to my existing system that I just could not decide on the best approach. In the end I think the attached is how I plan to go about it. Can anyone give me feedback on this? Am I making any terrible mistakes? I am trying to make use of as much as possible with what I already have in place. Given that I don't have time to tear everything apart and start from scratch.

I don't currently have storage but would like to plan it in to add later if possible.

Comments?