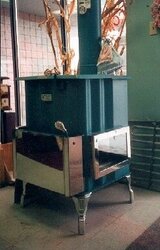

This seems to be one of the lastest rages in

stove combustion technology, where the

exhaust is pulled-down throught the coals,

thus resulting in cleaner, more even burns.

I know that Harman & V.C. make such stoves.

Does anyone have any experience with such a

unit?? Are the burns indeed longer & more "even"

(much like a catalytic stove)??

Thanks,

Rob

stove combustion technology, where the

exhaust is pulled-down throught the coals,

thus resulting in cleaner, more even burns.

I know that Harman & V.C. make such stoves.

Does anyone have any experience with such a

unit?? Are the burns indeed longer & more "even"

(much like a catalytic stove)??

Thanks,

Rob