Hi all.

I wanted to share my install with you and review its performance compared to several other stoves I have owned over the years. First of all, this site is great! Haven't posted much but enjoy reading all of the posts. I figured I should post my project to maybe inspire others in their pursuit of the perfect stove install

Little background. Graduated college and bought a house in 1997 in November. House had zero clearance steel fireplace. Worthless for heating right?? Pretty much! Installed Quadrafire 2100i into it and turned it into a heating machine! What college kid dreams of a wood burning stove?? Me I guess.

Moved in 2003 into another house that had a zero clearance fireplace. Had maybe two fires in it and went to wife saying its gotta go Enter quadrafire 7100 FP. Awesome stove/fireplace! Cranked the heat and looked good while doing so. After a few years, I started thinking about doing something different. Deep down I had always wanted a free standing stove. I found this site and just lurked.... for a few years. Discovered the Woodstock line of stoves and liked what I heard about heat retention, burn times, and just the overall high ratings that people gave it. Plus I really liked the way it looked. Pretty unique looking in my opinion. So I started planning..... Sprung the idea on the wife over pizza in Ames, IA. She was all in (she's a keeper) and began demo. Just prior to this, I was fortunate enough to actually see a fireview in person. I saw a review done by someone in Des Moines IA and gave them an email shout. He let me take a peak at it. As for you out there wondering about it's heating power, this person lives in a 3000+ house that is wide open with 20 + feet ceilings so volume wise it is more like 4500 sq feet in my best estimation in Iowa. He heats primarily with this stove and uses the furnace a little in the mornings and evenings to bring it back up to temp. Impressive IMHO.

Enter quadrafire 7100 FP. Awesome stove/fireplace! Cranked the heat and looked good while doing so. After a few years, I started thinking about doing something different. Deep down I had always wanted a free standing stove. I found this site and just lurked.... for a few years. Discovered the Woodstock line of stoves and liked what I heard about heat retention, burn times, and just the overall high ratings that people gave it. Plus I really liked the way it looked. Pretty unique looking in my opinion. So I started planning..... Sprung the idea on the wife over pizza in Ames, IA. She was all in (she's a keeper) and began demo. Just prior to this, I was fortunate enough to actually see a fireview in person. I saw a review done by someone in Des Moines IA and gave them an email shout. He let me take a peak at it. As for you out there wondering about it's heating power, this person lives in a 3000+ house that is wide open with 20 + feet ceilings so volume wise it is more like 4500 sq feet in my best estimation in Iowa. He heats primarily with this stove and uses the furnace a little in the mornings and evenings to bring it back up to temp. Impressive IMHO.

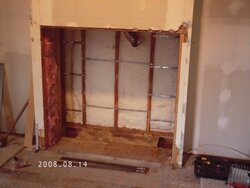

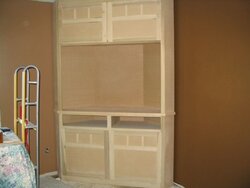

My install included basically redoing our entire family room from floor to ceiling including a new window. As if installing just a stove is not enough!

Back just a year ago when I started my install, there were a few posts hear and there about Woodstock Stoves and coming back this fall, seems like there are more and more of us out there! Over the next few days I will post a few pictures of my install and end this post with a 1 year review of what I think of this stove. Stay tuned!! I hope you enjoy!!

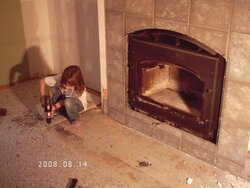

Here is a picture of the Quadrafire 7100fp before I got started:

I wanted to share my install with you and review its performance compared to several other stoves I have owned over the years. First of all, this site is great! Haven't posted much but enjoy reading all of the posts. I figured I should post my project to maybe inspire others in their pursuit of the perfect stove install

Little background. Graduated college and bought a house in 1997 in November. House had zero clearance steel fireplace. Worthless for heating right?? Pretty much! Installed Quadrafire 2100i into it and turned it into a heating machine! What college kid dreams of a wood burning stove?? Me I guess.

Moved in 2003 into another house that had a zero clearance fireplace. Had maybe two fires in it and went to wife saying its gotta go

Enter quadrafire 7100 FP. Awesome stove/fireplace! Cranked the heat and looked good while doing so. After a few years, I started thinking about doing something different. Deep down I had always wanted a free standing stove. I found this site and just lurked.... for a few years. Discovered the Woodstock line of stoves and liked what I heard about heat retention, burn times, and just the overall high ratings that people gave it. Plus I really liked the way it looked. Pretty unique looking in my opinion. So I started planning..... Sprung the idea on the wife over pizza in Ames, IA. She was all in (she's a keeper) and began demo. Just prior to this, I was fortunate enough to actually see a fireview in person. I saw a review done by someone in Des Moines IA and gave them an email shout. He let me take a peak at it. As for you out there wondering about it's heating power, this person lives in a 3000+ house that is wide open with 20 + feet ceilings so volume wise it is more like 4500 sq feet in my best estimation in Iowa. He heats primarily with this stove and uses the furnace a little in the mornings and evenings to bring it back up to temp. Impressive IMHO.

Enter quadrafire 7100 FP. Awesome stove/fireplace! Cranked the heat and looked good while doing so. After a few years, I started thinking about doing something different. Deep down I had always wanted a free standing stove. I found this site and just lurked.... for a few years. Discovered the Woodstock line of stoves and liked what I heard about heat retention, burn times, and just the overall high ratings that people gave it. Plus I really liked the way it looked. Pretty unique looking in my opinion. So I started planning..... Sprung the idea on the wife over pizza in Ames, IA. She was all in (she's a keeper) and began demo. Just prior to this, I was fortunate enough to actually see a fireview in person. I saw a review done by someone in Des Moines IA and gave them an email shout. He let me take a peak at it. As for you out there wondering about it's heating power, this person lives in a 3000+ house that is wide open with 20 + feet ceilings so volume wise it is more like 4500 sq feet in my best estimation in Iowa. He heats primarily with this stove and uses the furnace a little in the mornings and evenings to bring it back up to temp. Impressive IMHO.My install included basically redoing our entire family room from floor to ceiling including a new window. As if installing just a stove is not enough!

Back just a year ago when I started my install, there were a few posts hear and there about Woodstock Stoves and coming back this fall, seems like there are more and more of us out there! Over the next few days I will post a few pictures of my install and end this post with a 1 year review of what I think of this stove. Stay tuned!! I hope you enjoy!!

Here is a picture of the Quadrafire 7100fp before I got started:

Waiting to see that come in too....

Waiting to see that come in too....