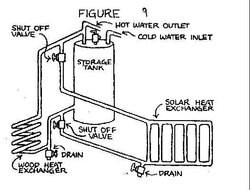

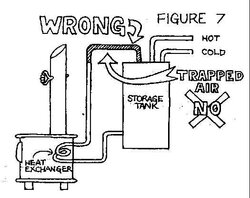

You must have the tank close to or above the coils. You should also have a check valve in the loop to keep the flow going the intended direction (make sure to put the lines in the proper places, if they are backwards, it wont work). The other thing that is key is making sure one end of the coil/HX is cooler that the other... you need the delta to get the thermosyphoning.

Hot Water

- Thread starter kenny chaos

- Start date

-

Active since 1995, Hearth.com is THE place on the internet for free information and advice about wood stoves, pellet stoves and other energy saving equipment.

We strive to provide opinions, articles, discussions and history related to Hearth Products and in a more general sense, energy issues.

We promote the EFFICIENT, RESPONSIBLE, CLEAN and SAFE use of all fuels, whether renewable or fossil.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Status

- Not open for further replies.

Wet1 said:You must have the tank close to or above the coils.

My trials were made with the heater core inlet just slightly above the outlet from the stove coil... and the outlet from the heater core above the inlet to the coil... all told a vertical rise of only a foot or so.

I thought that was what I had to do (at a minimum) and that keeping the core low would reduce the 'work' required to move the water. Is there a rule of thumb how much higher the tank (or 'receiving' container) must be above the coil outlet?

There is definitely a temp differential in the coils from bottom to top... from barely warm to the touch to 'untouchable'.

I was in fact able to get the water to move through the system, but it was intermittent... and I think the 'push' came from steam bubbles rather than thermosiphon action.

It was also an open system, with an expansion tank 'keep full' overflow... something like a modern car's cooling system... but without a pressure cap.

Anyways... I'd like to play some more with what I have on hand, but my last time 'out' - over ten years ago - I still had trouble with smooth circulation, and would like to better understand why before my next attempt.

Thanks for your reply.

Peter B.

-----

Peter B. said:I was in fact able to get the water to move through the system, but it was intermittent... and I think the 'push' came from steam bubbles rather than thermosiphon action.

It was also an open system, with an expansion tank 'keep full' overflow... something like a modern car's cooling system... but without a pressure cap.

-----

I suspect you did not have enough veritcal rise in the heating water. Thermosiphon works by vertical rise of cold to hot. The more rise (distance of bottom to top) and more water, the better it works. A heater core holds little water, has little verical rise, and has small passages internally. Many old cars and farm tractors used thermosiphon systems 100%. Many newer cars even with water pumps, are still - techincally a hybrid cooling system that uses forced circulation along with some degree of thermosiphon.

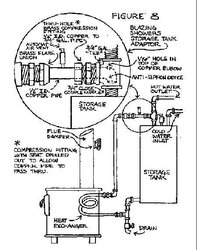

I've built many thermo-siphon systems over the years and all work, just about flawlessly. I've always used fairly high vertical tanks - usually electric hot water heaters that I got free or dirt cheap. Right now, my tank is an 80 gallon electric heater (electric not hooked up). The system I have now has a few refinements I added. A one-way check valve - 1/2" in the bottom cold water line as it enters the furnace coil. On top where the coil exits the furnace I have a vent that is there to make sure no air gets trapped in the coils. These parts are standard plumbing stuff and cheap.

The only problem I've ever had is due to hard water full of minerals. You need a way to flush the coils once in awhile. In my case, at least once a year. With the slow-flow, deposits build up in the coils. I used to take mine off every year and then clean it. Now, I installed a set of valve along with a garden hose hookup. I can backflush the coils now without removing.

My other problem is too much hot water when it's below zero outside, the furnace is going full blast for many days straight. As things are now, we turn on the hot water faucet before going to bed and let it run for 10-15 minutes. That's a waste of hot water - but if I don't do it that way, the 80 gallon tank gets too hot and the TP valve lets off. Someday, I might stick in an aquastat and circulator that will only come on when the entire tank is hot. Where I'm going to use that water, I don't know yet? Maybe I'll pipe it to my barn and hook to a radiator or baseboard heat-exchanger. A now deceased friend of mine did something funny years back. He lived in a small modular home but had a big wood furnace with hot water coils. He piped hot water under his driveway and - during the worst parts of the winter, had a heated driveway that the ice and snow melted fast. Looked pretty weird on a sub-zero day to see steam coming off his driveway.

jdemaris said:I suspect you did not have enough veritcal rise in the heating water. Thermosiphon works by vertical rise of cold to hot.

Thanks for this...

I'll be thinking about how best to make another trial setup... with a greater vertical rise... and at least minimal storage.

By the way, I liked the heated driveway 'concept'... it sure would have come in handy here the past two winters.

A (now deceased) friend of my own used to heat domestic hot water with a loop from an antique cook stove firebox to a steel tank. I now assume it was a thermosiphon setup, but I never looked closely at the plumbing.

--

kenny chaos: Sorry to have (halfway) hijacked your thread.

Peter B.

-----

[quote author="Peter B." date="1232425586

--

kenny chaos: Sorry to have (halfway) hijacked your thread.

Peter B.

-----[/quote]

No problem Dude.

--

kenny chaos: Sorry to have (halfway) hijacked your thread.

Peter B.

-----[/quote]

No problem Dude.

EngineRep said:[ Modern stoves operate around 80% efficiency, meaning "only" 20% of the heat gets to the flue in the first place. Say this device can recover half of that (probably not a bad estimate -- the best aerospace heat exchanges only get to 80% or so when operating exactly at the design point). So you would effectively be extracting an additional 10% of the energy out of wood or oil or whatever and for that you'd be installing a $500 device, plus installation and plumbing costs, and paying for the electricity to pump it back into the house. Not for me!

Rep-

My Lopi Liberty is listed as 70%. So if 30% is going up the flue and this gadget can reclaim 35% of that, at a constant interior flue temp of 550 degrees, when burning 1/3 facecord of good mixed hardwoods/wk, how many BTU's/hr can this recover?

Peter B. said:By the way, I liked the heated driveway 'concept'... it sure would have come in handy here the past two winters.

Same guy that had the wood-heated driveway also built a four-wheel drive outhouse/dunebuggy. Don't ask me why, it was just something he wanted to have to drive on the beach somewhere (we don't have any beaches around here). He was an almost-always stoned welder and built some interesting stuff. He moved to Florida around 10 years ago, and I just saw his name in the obituary. I was kind of shocked to see he was 70 something. But, when you know someone for 40 years, I guess they tend to age.

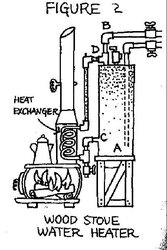

About thermosiphon, it's a very old and reliable system - nothing new about it. Many old wood kitchen stoves would have a small heating coil hooked to a tank mounted high above the stove for hot water storage and they worked great.

Along the same line, the old gravity hot-air wood and coal furnaces also worked very well. I wish I could have one, but they only work when the house is built to use it. Usually a multi-story veritcal house with a deep cellar. Gravity hot-air furnace uses big heat pipes since there's no blower. My biggest gripe about my wood furnace is the damn blower running just about all the time. It uses a lot of power. Granted I'm on solar-electric, but that isn't exactly free either.

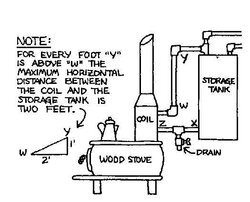

Here are a few crude diagrams with some info on some wood heat thermosiphon hookups.

Attachments

kenny chaos said:Rep-

My Lopi Liberty is listed as 70%. So if 30% is going up the flue and this gadget can reclaim 35% of that, at a constant interior flue temp of 550 degrees, when burning 1/3 facecord of good mixed hardwoods/wk, how many BTU's/hr can this recover?

Heat energy in one cord ~ 24 million BTU

Heat energy in one face cord ~ 8 million BTU

Heat energy in 1/3rd face cord ~ 2.67 million BTU

Heat saved by this device is .3*.35*2.67 million, or about 280,000 BTU/week (that's about 2 gallons of oil or less than $5.00 at today's prices).

EDIT: didn't go quite as far as you asked... that's about 1670 Btu/hr.

jdemaris said:Along the same line, the old gravity hot-air wood and coal furnaces also worked very well. I wish I could have one, but they only work when the house is built to use it.

Only this year, a local friend of mine (still with us) 'upgraded' from a built-in Green Colonial basement wood/coal furnace to an OWB... after thirty years continuous use. (Of course the furnace was in place (and in use) long before my friend bought the house.) Built in with the furnace was an elaborate convection shroud and ducting to most rooms of the house.

I was sorry to see him abandon the Colonial, and I offered to help him bring it back to a reasonably seviceable condition, but he wouldn't go for it. And he says he's actually burning substantially less wood now with the OWB than with the basement furnace.

He may have run countless more cords through the Colonial than he needed to, but he didn't mind all that much, enjoys 'making' firewood on his forty acres, and claims he kept the old farmhouse between 75 and 85* degrees most of the winter... though it required five trips to the basement for reloads every day.

I would likely kill to recreate a similar convection system in my own older house... and tinker with the burn characteristics of the furnace til death do us part... but you're right, they both really need to be built with the house.

Anyways...

Thank you for the additional diagrams... good to have some simple 'pitchurs' to study up with.

Peter B.

-----

If your unit took all of the heat it could and put into the ducting there wood be no need to extract extra btu's from the flue gas temps.

Smoke is a gas and will condense at around 300 degrees.

An 80 % oil furnace for example will have a 400 degree stack temp at .03" of watercolumn tested out with a manometer.

Wood can be about 70-75% efficient at best.

Any higher % and the gases being exhausted are too cool to create a good natural draft and will cause back drafting.

Smoke is heavy and needs 400 degrees to expell it properly.

Burning wood also needs to be able to burn smoke to make all 8000 btu's available at 20% moisture content.

Smoke can provide up to 40% of your heat. The real test is to see if your chimney is emmiting a bunch of smoke.If the answer is yes you are waisting a ton of heat that could be made and exchanged into your home.

http://www.yukon-eagle.com/FURNACES/EAGLEIHUSKY/tabid/55/Default.aspx

You'll see in this diagram the secondary air tube/jet air that reburns gases.

There are other ways like catilytic,but they can be high maintanence.Once they plug your your back to loosing those efficiencies.

Smoke is a gas and will condense at around 300 degrees.

An 80 % oil furnace for example will have a 400 degree stack temp at .03" of watercolumn tested out with a manometer.

Wood can be about 70-75% efficient at best.

Any higher % and the gases being exhausted are too cool to create a good natural draft and will cause back drafting.

Smoke is heavy and needs 400 degrees to expell it properly.

Burning wood also needs to be able to burn smoke to make all 8000 btu's available at 20% moisture content.

Smoke can provide up to 40% of your heat. The real test is to see if your chimney is emmiting a bunch of smoke.If the answer is yes you are waisting a ton of heat that could be made and exchanged into your home.

http://www.yukon-eagle.com/FURNACES/EAGLEIHUSKY/tabid/55/Default.aspx

You'll see in this diagram the secondary air tube/jet air that reburns gases.

There are other ways like catilytic,but they can be high maintanence.Once they plug your your back to loosing those efficiencies.

- Status

- Not open for further replies.

Similar threads

- Replies

- 4

- Views

- 2K

- Replies

- 1

- Views

- 376

- Replies

- 13

- Views

- 815

- Replies

- 17

- Views

- 707