Look what I found when I tore my old fireplace out.

- Thread starter tlhfirelion

- Start date

-

Active since 1995, Hearth.com is THE place on the internet for free information and advice about wood stoves, pellet stoves and other energy saving equipment.

We strive to provide opinions, articles, discussions and history related to Hearth Products and in a more general sense, energy issues.

We promote the EFFICIENT, RESPONSIBLE, CLEAN and SAFE use of all fuels, whether renewable or fossil. -

Super Cedar firestarters 30% discount Use code Hearth2024 Click here

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Status

- Not open for further replies.

- Aug 6, 2007

- 442

BeGreen said:tlhfirelion said:ok so here is the pic of the area I am looking at having the pass thru to the old chase and up and out. In case you can't see the measurements they are 27" from the bottom of the header seen and the one that the roof joists r sitting on. The other one from the outside studs is 43.5". I assume I would need to remove the two inner studs in this pic to then have a combustible clearance needed assuming the thimble would remove the drywall to the proper distance???????

Slowdown and don't do more demolition work until you have downloaded and read some installation manuals for chimney flues. Also, be careful to use the right terminology because it can be confusing and misleading to just say double-wall. For simplicity sake, let's use Simpson Duravent pipe terms.

For the interior flue piping you will use DVL double wall pipe. It needs a minimum of 6" clearance to combustibles. For everything on the other side of the wall you will use class A double-wall pipe (DuraTech). This class A pipe has a minimum 2" clearance requirement. Now, for the moment lets ignore the boxed exterior chase. Assume it isn't even there. What you will be constructing is an exterior class A flue, hopefully with a clean out tee on the bottom. There will be a short horiz. class A pipe that extends from the tee, through the thimble, 6" into the room. The thimble is an adjustable bracket that maintains the 2" clearances. You shouldn't need to remove any of the existing vertical studs as long as the flue is centered on one of the existing stud spaces. If not, you will need to box it in. Does that make sense? From that stub of class A now sticking 6" into the room you will transition to the 6" double wall interior pipe for a short horizontal run, then an elbow directly over the stove flue connector and straight down to link the stove to the elbow. Try to be sure that the horiz. connecting pipe between the elbow and the thimble is pitched uphill 1/4" per foot. Smoke does not go downhill very well.

Simpson installation instructions:

http://www.duravent.com/?page=ts.php (choose from the second popup menu - DuraTech 5"-8")

Look at figure 24 on page 17 for a diagram of how the thimble works in conjunction with the clean out tee. Figure 27 is close to what your setup will look like, but you have a top vented stove so up to an elbow and then connect to that to the thimble.

excellent reply man, I understand what you are explaining and thats what I was seeing in my head. I guess weather the chase is there or not is irrelevant since it's got much more clearance than is needed so it's a non issue. The only problem I see with that is how to access the chase from the outside to clean out the "T" but thats an easier problem to solve from the outside and for another day. In the chase area I assume I can use the galvanized double wall correct?

- Aug 6, 2007

- 442

rdrcr56 said:In the picture of your opening is that horizontal stud what you are talking about as 46 in. high?

No I'm referring to the beam that can only be seen from inside the chase that is towards the top of the wall.

Well I guess I cant picture the framing of your wall, so what I'm trying to get across is that where the ceiling and the wall meet that is where the load bearing joist should be, you should be able to remove the wall that was above your old fireplace up to close to the ceiling.

- Aug 6, 2007

- 442

rdrcr56 said:Well I guess I cant picture the framing of your wall, so what I'm trying to get across is that where the ceiling and the wall meet that is where the load bearing joist should be, you should be able to remove the wall that was above your old fireplace up to close to the ceiling.

You are correct, we are seeing the same thing in our head, just explaining it different. That load bearing joist is what is in the way of me getting my proper clearances for an alcove set up. No worries man thanks for your help.

- Aug 6, 2007

- 442

I got delayed on working on my fireplace but am back at it now. I have constructed the hearth pad out of 2X4 construction (14" on center) with 1" plywood on top and facing the front of it. (it is a raised hearthpad) My plan is to now put 2 layers of durock on this plywood, the the thinset and the hearth stones/stone veneer. I will have have all the proper clearances per my stoves manual. Before I continue, would you agree or disagree that so far I am doing this correctly?

- Aug 6, 2007

- 442

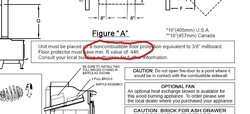

Actually it appears (see chart from hearth.com below) I could easily use only 1 sheet of durock on the hearth pad. My stove manual states I need floor protection equiv. to 3/8th" millboard and an r value of .446. I could use only 1 sheet of durock on my 1" plywood, and then put the stove veneer on that and still be over the requirements. Correct?

Considering that at some point in the future you might want to upgrade the stove, perhaps build it slightly oversized and over-spec? If you agree, put a layer of micore on top of the plywood, then a layer of sheetmetal, then a single top layer of durock. Screw the sandwich together per durock's recommended interval. That would give you a more future-proof hearth for just a few more bucks.

- Aug 6, 2007

- 442

BeGreen said:Considering that at some point in the future you might want to upgrade the stove, perhaps build it slightly oversized and over-spec? If you agree, put a layer of micore on top of the plywood, then a layer of sheetmetal, then a single top layer of durock. Screw the sandwich together per durock's recommended interval. That would give you a more future-proof hearth for just a few more bucks.

Well I can tell you we are talking about building a home in about 2 years so this will be our last hearth construction here. There is zero chance of us upgrading the stove in this home. I must admit I was rather surprised at how small of an r value this stove needed but I must remember it is a small stove compared to those that some of you guys have. As always thanks for your reply!

- Aug 6, 2007

- 442

fossil said:This copied & pasted from USG:

"DUROCK Brand Cement Board has an R value of 0.26"

Rick

OK, so I have 1" plywood, 1 sheet of durock, then hearth stone and mortar and I only need .446 for my r value. Well I feel I am operating safely by proceeding. Thanks man.

- Aug 6, 2007

- 442

Not sure why you keep mentioning the 1" of plywood. Plywood's a combustible. All the required insulative value needs to be between the stove and the combustible. The plywood has nothing to do with the required r-value of the hearth. Just wanting to make sure I understand. The mortar buys you next to nothing, and I'm not sure what you mean by hearth stone, but if it's some sort of stone veneer, than it doesn't have much r-value either. Rick

Rick, thanks for waking me up - firelion, is this for the Century 27007 stove? I assumed you were following the manual which now that I re-read it calls for R.893 or better on the hearth. So far you have only R .52. If you go back to my original instructions you will be good to go.

Are my docs in conflict with your's?

EDIT:

Argh! Documentation department please! Now I see what you are seeing too. And it says .446 for the same 3/8" millboard. So you are OK as you are following the stove specifications.

Are my docs in conflict with your's?

EDIT:

Argh! Documentation department please! Now I see what you are seeing too. And it says .446 for the same 3/8" millboard. So you are OK as you are following the stove specifications.

Attachments

- Aug 6, 2007

- 442

BeGreen said:Rick, thanks for waking me up - firelion, is this for the Century 27007 stove? I assumed you were following the manual which now that I re-read it calls for R.893 or better on the hearth. So far you have only R .52. If you go back to my original instructions you will be good to go.

Are my docs in conflict with your's?

Yes they do conflict my docs. I am looking right at it and the portion os the 3/8th inch millboard and the floor protector must have a min. r value of .446. Would the legs versus pedestal have anything to do with this?

- Aug 6, 2007

- 442

actually I think the leg/ped. thing is the difference. If you look on the image you put up, up in the top left hand corner you will see a pic of your stove and the clearance pic to the roof. Yours shows the stove with legs and mine with the stand.

No, see above post. This is a mess up with Century's documentation or you have a different model. What is the correct model number for your stove?

You can go by the specs you have. If questioned, you have the paperwork to prove it.

You can go by the specs you have. If questioned, you have the paperwork to prove it.

- Aug 6, 2007

- 442

BeGreen said:Rick, thanks for waking me up - firelion, is this for the Century 27007 stove? I assumed you were following the manual which now that I re-read it calls for R.893 or better on the hearth. So far you have only R .52. If you go back to my original instructions you will be good to go.

Are my docs in conflict with your's?

EDIT:

Argh! Documentation department please! Now I see what you are seeing too. And it says .446 for the same 3/8" millboard. So you are OK as you are following the stove specifications.

what on earth?? So which manual do I follow?

- Aug 6, 2007

- 442

BeGreen said:No, see above post. This is a mess up with Century's documentation. You can go by the specs you have. If questioned, you have the paperwork to prove it.

Well, thats good but is this a major safety problem or what? How do I know my paperwork is correct and not yours or vice versa?

Follow your paperwork - what the exact model of your stove. The higher hearth R value is for the 27007.

- Aug 6, 2007

- 442

fossil said:Not sure why you keep mentioning the 1" of plywood. Plywood's a combustible. All the required insulative value needs to be between the stove and the combustible. The plywood has nothing to do with the required r-value of the hearth. Just wanting to make sure I understand. The mortar buys you next to nothing, and I'm not sure what you mean by hearth stone, but if it's some sort of stone veneer, than it doesn't have much r-value either. Rick

I don't have a clue why I mentioned it, guess I just wanted to brag. lol

- Aug 6, 2007

- 442

BeGreen said:Follow your paperwork - what the exact model of your stove. The higher hearth R value is for the 27007.

I have the fw240007 and it says that on the sticker on the back of my stove. The manual says for either 0007 or 0008.

If you need .446, then slap in two layers of 1/2" Durock and be done with it. Forget about figuring in the mortar and stone veneer, they have r-values an order of magnitude below Durock...they'll add up to 0.0xx, just ignore them. Rick

That probably explains the difference. Earlier on I asked if this was the 270007 and got an affirmative. It seems the 270007 is a bigger stove and requires a bit more protection. Sorry for the confusion. It doesn't explain the confusing language of the docs, but you are covered. Just screw that sucker together and put your heater on it.

- Status

- Not open for further replies.

Similar threads

- Replies

- 22

- Views

- 1K

- Replies

- 5

- Views

- 1K

- Replies

- 3

- Views

- 417

- Replies

- 8

- Views

- 446