setback thermostats and Harman Pellet stoves

- Thread starter HarryBack

- Start date

-

Active since 1995, Hearth.com is THE place on the internet for free information and advice about wood stoves, pellet stoves and other energy saving equipment.

We strive to provide opinions, articles, discussions and history related to Hearth Products and in a more general sense, energy issues.

We promote the EFFICIENT, RESPONSIBLE, CLEAN and SAFE use of all fuels, whether renewable or fossil. -

Super Cedar firestarters 30% discount Use code Hearth2024 Click here

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

It's a P43. Brand new last September.

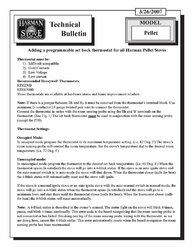

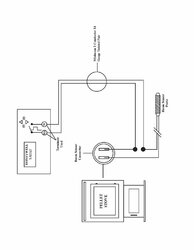

Someone at Harman finally got back to me with the PDF of their tech note. I am attaching it here for anyone else who might want it.

According to their diagram, it looks like I have it wired correctly. They don't indicate that it matters which wire (red/black) that you connect the t-stat to. So maybe i just need to be patient and give the stove time to shut down.

What's weird is when testing. The stove is cold and set to room-temp mode and t-stat would be off. I'd click the t-stat on. The stove would pick up the signal and begin startup. Then I'd click the t-stat back off, but the stove would continue to run and feed pellets, even with the 4-blink status. I didn't wait very long to see if it would eventually shut back off. I figured I had a problem and manually turned the stove back off.

Someone at Harman finally got back to me with the PDF of their tech note. I am attaching it here for anyone else who might want it.

According to their diagram, it looks like I have it wired correctly. They don't indicate that it matters which wire (red/black) that you connect the t-stat to. So maybe i just need to be patient and give the stove time to shut down.

What's weird is when testing. The stove is cold and set to room-temp mode and t-stat would be off. I'd click the t-stat on. The stove would pick up the signal and begin startup. Then I'd click the t-stat back off, but the stove would continue to run and feed pellets, even with the 4-blink status. I didn't wait very long to see if it would eventually shut back off. I figured I had a problem and manually turned the stove back off.

Attachments

There's nothing wrong with what they suggested here, but it does strike me as a bit unprofessional to rely on an error situation to produce the setback. Though one could also call it a clever trick!

It is important to follow the directions regarding setting the thermostat's normal mode temp to the max. Otherwise there could be a continuing duel between it and the stove's own setting that leads to an unstable situation.

Choice of which wire is which would make no difference in any of the schemes we've discussed here. Polarity isn't relevant in situations that simply involve on/off or changing resistance.

It is important to follow the directions regarding setting the thermostat's normal mode temp to the max. Otherwise there could be a continuing duel between it and the stove's own setting that leads to an unstable situation.

Choice of which wire is which would make no difference in any of the schemes we've discussed here. Polarity isn't relevant in situations that simply involve on/off or changing resistance.

Three3 said:It is important to follow the directions regarding setting the thermostat's normal mode temp to the max. Otherwise there could be a continuing duel between it and the stove's own setting that leads to an unstable situation.

No and yes. See my sig for an alternative I've been running all winter with excellent results.

So I'm bringing up an old thread, but I have another approach to this problem I'd like to throw out there. Three3, what about this:

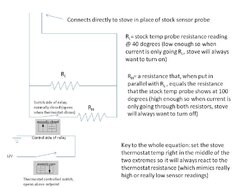

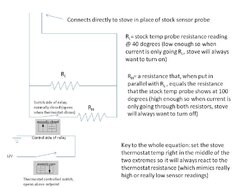

Instead of creating a circuit that modifies the resistance of the stock temp probe (thermister), what about completely doing away with the stock probe and controlling the resistance yourself? This way you can create true thermostat control. Here is my theory:

1: take off the temperature probe. Put it in the fridge for a while, read the resistance, call it RL (Should be a high resistance)

2: put the probe somewhere hot, like near 100 degrees. Take a resistance reading, call it RHtotal (should be much lower)

3: find the Rh value. Should be Rh = (Rhtotal * RL)/(RL - RHtotal) (this gives you the actual resistor value that, when put in parallel with RL, will give you RHtotal, which should be a lower value than RL)

And then you just make a circuit that uses these. The extra relay in the ciruit is because, when a standard thermostat is above its setpoint (which means heat should turn off), it opens a switch. We basically need to reverse that, so I accomplished that by making the thermostat swtich control a second relay that is "normally closed" to reverse its actions. This means that when the thermostat says "turn the heat off", the relay in the circuit that matters will actually close instead of open.

Here's what happens:

You use a standard programmable thermostat that will close a circuit when the temp drops below its designated temp and open it back up when it warms above its setpoint. You create the circuit below. When the thermostat says it is above its setpoint, the thermostat switch will be open, which means the relay in the resistance circuit will be closed. This will reduce the total resistance to Rhtot, which will tell the stove it is 100 degrees in the room, so the stove will turn off.

When the thermostat calls for heat because the room temp is below the setpoint, it will close its circuit, which will open up the relay in the resistance circuit. This will send all the current through RL, which will tell the stove it's 40 degrees in the room, so it needs to turn on.

All of this hinges on the fact that the stove is set at a temp somewhere around 70 degrees... this will make it always turn on when it sees a resistance value equal to 40 degrees and always turn off when it sees a resistance value of 100 degrees.

What do you think?

Here is a circuit... I'm not good with the "real" symbols for stuff, but I think the point gets across:

Instead of creating a circuit that modifies the resistance of the stock temp probe (thermister), what about completely doing away with the stock probe and controlling the resistance yourself? This way you can create true thermostat control. Here is my theory:

1: take off the temperature probe. Put it in the fridge for a while, read the resistance, call it RL (Should be a high resistance)

2: put the probe somewhere hot, like near 100 degrees. Take a resistance reading, call it RHtotal (should be much lower)

3: find the Rh value. Should be Rh = (Rhtotal * RL)/(RL - RHtotal) (this gives you the actual resistor value that, when put in parallel with RL, will give you RHtotal, which should be a lower value than RL)

And then you just make a circuit that uses these. The extra relay in the ciruit is because, when a standard thermostat is above its setpoint (which means heat should turn off), it opens a switch. We basically need to reverse that, so I accomplished that by making the thermostat swtich control a second relay that is "normally closed" to reverse its actions. This means that when the thermostat says "turn the heat off", the relay in the circuit that matters will actually close instead of open.

Here's what happens:

You use a standard programmable thermostat that will close a circuit when the temp drops below its designated temp and open it back up when it warms above its setpoint. You create the circuit below. When the thermostat says it is above its setpoint, the thermostat switch will be open, which means the relay in the resistance circuit will be closed. This will reduce the total resistance to Rhtot, which will tell the stove it is 100 degrees in the room, so the stove will turn off.

When the thermostat calls for heat because the room temp is below the setpoint, it will close its circuit, which will open up the relay in the resistance circuit. This will send all the current through RL, which will tell the stove it's 40 degrees in the room, so it needs to turn on.

All of this hinges on the fact that the stove is set at a temp somewhere around 70 degrees... this will make it always turn on when it sees a resistance value equal to 40 degrees and always turn off when it sees a resistance value of 100 degrees.

What do you think?

Here is a circuit... I'm not good with the "real" symbols for stuff, but I think the point gets across:

Is there a difference between a Trim Pot and a Potentiometer? I installed a 50k- Ohm Potentiometer today and it gave me a 4 flash error on the Harman when it went to cool down mode. I even took the programmable thermostat and hooked up the Pot. up directly in parallel with the thermister and still got the 4 flash error code.

Is there a difference between a Trim Pot and a Potentiometer? I installed a 50k- Ohm Potentiometer today and it gave me a 4 flash error on the Harman when it went to cool down mode. I even took the programmable thermostat and hooked up the Pot. up directly in parallel with the thermister and still got the 4 flash error code.

Got it! I had to link the middle with one of the sides, now everything appears to be working correctly.

bmccue

Member

I have had a Harmon P43 pellet stove for about 3 years now. I have a setback wall thermostat installed next to the one I have for my "regular" forced hot air system (which is now locked at 50 degrees).

Hookup was easy. I actually cut BOTH of the sensor leads coming out of the back and lengthened them so they could be routed through basement and back up to wall thermostat installed for pellet stove. I then wired the room sensing probe in series with the thermostat itself and managed to place this probe inside of the thermostat housing itself. I have my ROOM TEMP setting on the stove set to about 75. When there's a call for heat, the stove is actvated and the stove attempts to reach a temperature of 75 at the room sensor probe (now in the thermostat housing). However, the thermostat is set to 70 so it opens the series circuit before the stove hits that temperature. At that point the status light flashes 4 times and the stove effectively goes into shut down mode.

I keep my "regular" furnace thermostat set to 50 in the event that the pellet stove runs out of pellets. This is to keep the house from freezing (I live in NH).

System has worked quite well for 3 years and it provides 100% of the heat for my 2000 Square Foot two story house for about $600 year (propane was about $1,800).

Hookup was easy. I actually cut BOTH of the sensor leads coming out of the back and lengthened them so they could be routed through basement and back up to wall thermostat installed for pellet stove. I then wired the room sensing probe in series with the thermostat itself and managed to place this probe inside of the thermostat housing itself. I have my ROOM TEMP setting on the stove set to about 75. When there's a call for heat, the stove is actvated and the stove attempts to reach a temperature of 75 at the room sensor probe (now in the thermostat housing). However, the thermostat is set to 70 so it opens the series circuit before the stove hits that temperature. At that point the status light flashes 4 times and the stove effectively goes into shut down mode.

I keep my "regular" furnace thermostat set to 50 in the event that the pellet stove runs out of pellets. This is to keep the house from freezing (I live in NH).

System has worked quite well for 3 years and it provides 100% of the heat for my 2000 Square Foot two story house for about $600 year (propane was about $1,800).

grh372

Member

is there any reason why you have to keep the the room sensor in the loop? most pellet stoves you just run the wire to the digital thermostat and that controls the whole setup.

railfanron

Minister of Fire

Yes there is. The temperature sensor is a varistor and it varies with the temperature in the room. This give the control board something to compare against its internal electronics and that determines whether the heat turns on or off. A thermostat is nothing more than a temperature controlled switch that either makes or breaks depending on the temperature it's set at. By putting it in series you're basically switching the varistor, when turned off, into an open situation and that triggers the error condition that shuts down the stove. When the thermostat calls for heat it makes the connection and the error goes away and the stove starts up. Very simple and it works very nicely. I've been doing it for 2 years. It works equally well in either room temp automatic or manual modes.

Ron

Ron

Stroud

New Member

I'm getting older and lazy. I want my stove to start automatically say at 3 am will I'm still in bed, yes I said I was lazy. So I trying to utilize a stat to start and stop my stove.

Stroud

New Member

Yes there is. The temperature sensor is a varistor and it varies with the temperature in the room. This give the control board something to compare against its internal electronics and that determines whether the heat turns on or off. A thermostat is nothing more than a temperature controlled switch that either makes or breaks depending on the temperature it's set at. By putting it in series you're basically switching the varistor, when turned off, into an open situation and that triggers the error condition that shuts down the stove. When the thermostat calls for heat it makes the connection and the error goes away and the stove starts up. Very simple and it works very nicely. I've been doing it for 2 years. It works equally well in either room temp automatic or manual modes.

Ron

So if I us battery power and contacts R &W the stove sensor will control the stove and tstat can start & stop, tstat is just a timer. Do mil-volts come in to play?Yes there is. The temperature sensor is a varistor and it varies with the temperature in the room. This give the control board something to compare against its internal electronics and that determines whether the heat turns on or off. A thermostat is nothing more than a temperature controlled switch that either makes or breaks depending on the temperature it's set at. By putting it in series you're basically switching the varistor, when turned off, into an open situation and that triggers the error condition that shuts down the stove. When the thermostat calls for heat it makes the connection and the error goes away and the stove starts up. Very simple and it works very nicely. I've been doing it for 2 years. It works equally well in either room temp automatic or manual modes.

Ron

Similar threads

- Replies

- 0

- Views

- 824

- Replies

- 6

- Views

- 866

- Replies

- 2

- Views

- 2K

- Replies

- 0

- Views

- 665