You did ask before, and I gave a wishy-washy answer, because I really don't know. I hadn't been doing a good job of keeping track from which row the wood came, when I moved it from those wood racks in my wood lot, up to the house for burning. Also, because I'm very inconsistent in my split size (I guess my attitude on this varies by month/year), and because each rack contains a different species, there are really too many variables for me to be confident in any conclusion I could give today.

BUT... do note I'm not 3 or 4 rows deep, either. The sheds are open on

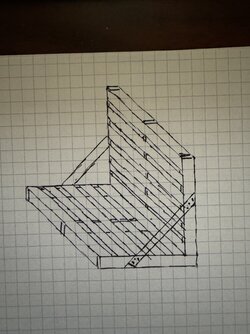

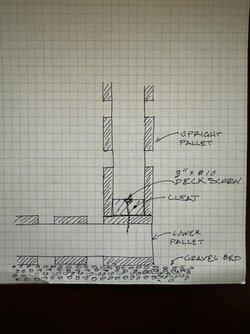

both faces, which was by design, both for airflow and easily accessibility. So it's not only a "blow thru" design, but also means no row of wood is more than "second row" deep from either side. Here's a goofy photo of one of them on the move from where I build them at my shop, down the hill to the wood lot where they're installed on piers, and you can see it's totally open on all sides, just a roof over four rows.

View attachment 323626

No, the wheels don't stay on it. That's just an old boat trailer axle I use for moving heavy things around the yard.

My advice to anyone is to make all sheds no more than 2 rows deep from any accessible side, lest you need to walk into them to retrieve wood. As it is now, I park my wagon next to the shed and literally dump wood right off the stack into the wagon.

View attachment 323625

They do, and as noted the low temperature limit has been trending downward over the years. They become horribly inefficient and terribly expensive to run at very cold temperatures, but if that's only a few days per year, that temporary high operating cost may still be less than the cost of installing or repairing a secondary system.