Hey guys. I love this site- I check it every day. I've got a question. Have any PE owners had trouble with warpage on their baffles? I have a Summit insert and am now on my second baffle. I'm babying it (it's still pretty warm here) but I'm seeing some sag in the baffle- it's not perfectly flat like it was when I installed it. I know I haven't overfired the stove- no glowing parts, I keep track of the temps with a thermometer on the front face, etc. Can't figure it out. I guess the second question is, does it matter? My first baffle sagged about 1/4" from the sides to the center. PE didn't have any great answers- they just sent me another baffle. Thanks in advance for any input!

warped baffles on PE stoves

- Thread starter davidfishlock

- Start date

-

Active since 1995, Hearth.com is THE place on the internet for free information and advice about wood stoves, pellet stoves and other energy saving equipment.

We strive to provide opinions, articles, discussions and history related to Hearth Products and in a more general sense, energy issues.

We promote the EFFICIENT, RESPONSIBLE, CLEAN and SAFE use of all fuels, whether renewable or fossil.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Status

- Not open for further replies.

webbie

Seasoned Moderator

1/4" would seem to be in the normal scheme of things. That should not affect wood load, capacity or burning.

Other members have probably not even looked that close - I'll let them look and answer for themselves.

Other members have probably not even looked that close - I'll let them look and answer for themselves.

fishercat

New Member

Mine sags in the back. A 1/4 inch sounds about right for mine also. I called Pacifac Energy office and they said overfire and a bunch of other excuses would do that. I've never overfired my stove and I only had about 20 fires in it. They give me a name of a local dealer so I called him. He told me that in order to get warrenty he would have to send the baffle away so they could look at it. Of couse he said it take up to 3 months. So since it's burning season I'll have to wait until the cold weather is gone. But it seems like a common problem. It doesn't seem to hurt the stove but I do notice secondary burn at the back of the stove so i would think air is getting in from that end.

Shane

Minister of Fire

stoveguy2esw

Minister of Fire

it may just be somthing that is inherant with that type stove , and might not move any more than that. im no PE expert so i cant say for sure. im sure that if that was a problem that caused burning issues with the unit there would be an acceptable answer or some kind of fix for it. does the unit exibit any different burning charactoristics after the baffles warp like that?

thechimneysweep

Minister of Fire

In the old days, PE used mild steel for their baffle boxes. My Spectrum has the mild steel baffle, and it's belly has sagged down a good 1/2" or so - in 15 years. It still works fine, and I don't consider it a defect. My bet is the new stainless boxes won't sag as much, but even if they do, I don't see how it could affect the burn.

Hogwildz

Minister of Fire

Heat any flat mass of steel to what about 1000 degrees inside that baffle, and its going to sag a lil. Doesn't affect burning, and secondary burn is secondary burn, so some happens at the back, its all good Keep in mind you heating a baffle box that is around 20" wide by close to the same deep. expect a small sag or belly. If you replace it, you'll get the same thing. Unless you burn at 300 degrees or less all the time, and then your not burning correctly.

Keep in mind you heating a baffle box that is around 20" wide by close to the same deep. expect a small sag or belly. If you replace it, you'll get the same thing. Unless you burn at 300 degrees or less all the time, and then your not burning correctly.

Keep in mind you heating a baffle box that is around 20" wide by close to the same deep. expect a small sag or belly. If you replace it, you'll get the same thing. Unless you burn at 300 degrees or less all the time, and then your not burning correctly.

Keep in mind you heating a baffle box that is around 20" wide by close to the same deep. expect a small sag or belly. If you replace it, you'll get the same thing. Unless you burn at 300 degrees or less all the time, and then your not burning correctly.webbie

Seasoned Moderator

I have never stuck my head too far inside these stoves, but a general comment is that very few stoves (if any) have FLAT pieces of steel in them, because you don't have to be an engineer to know that bends (and in these cases, welded stays, angles, etc) increase the strength by MANY times. Now you guys are not going to tell me that PE uses a plain flat piece of steel, are you?

E

elkimmeg

Guest

Hogwildz said:Heat any flat mass of steel to what about 1000 degrees inside that baffle, and its going to sag a lil. Doesn't affect burning, and secondary burn is secondary burn, so some happens at the back, its all goodKeep in mind you heating a baffle box that is around 20" wide by close to the same deep. expect a small sag or belly. If you replace it, you'll get the same thing. Unless you burn at 300 degrees or less all the time, and then your not burning correctly.

I agree then why don't they put a disclaimer in the manual so owner know what to expect. If I did not know and it warped after 5 fires I would be pissed. Just like seeing a dent in your new car it does not effect it driving, but sure would bother me. telling me it is a warranty issue but there is a 3 month backlog is plain bad customer relations and bad PR how good is a warranty if it takes your stove out of the burning season when they request you send it to them before replacement that sure would tick me off.

Shane

Minister of Fire

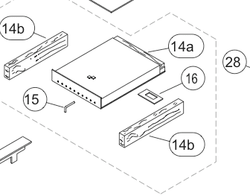

The PE baffles I remember are a stainless steel box with holes to deliver the secondary combustion air. The air is delivered by a center channel in the rear wall of the firebox. The baffle attaches and has a gasket when you set it in the brackets.

E

elkimmeg

Guest

I

I would be spitting bullets outraged at being treated this way. So much for customer support and warranty concerns the only thing missing here is the gun and mask

This has been an ongoing problem I think it time PE comes her and addresses our forum member's concerns. Lets face it, why design something that is going to warp right away after only a few fires and the treat its customers this way? That is totally unacceptable. IT's a design flaw no wonder it takes 3 months to replace it ,if it only last a few fires before warping ( probably because they ran out of replacements) That five fire limit is killing them)

I think it time PE steps up to the plate and explains this and what they intend to do about it..

Really these are not Vogelzangs but expensive stoves and one should expect and demand more. Tom what do you have to say you mail ordered quite a few here

if this was a new car, how happy would you be when the paint starts flaking off? The dealer tells you its ok ,it does not effect the way it drives and it is normal for it to do this?

maybe there should be a recall? class action suit?

’ve never overfired my stove and I only had about 20 fires in it. They give me a name of a local dealer so I called him. He told me that in order to get warrenty he would have to send the baffle away so they could look at it. Of couse he said it take up to 3 months. So since it’s burning season I’ll have to wait until the cold weather is gone. But it seems like a common problem

I would be spitting bullets outraged at being treated this way. So much for customer support and warranty concerns the only thing missing here is the gun and mask

This has been an ongoing problem I think it time PE comes her and addresses our forum member's concerns. Lets face it, why design something that is going to warp right away after only a few fires and the treat its customers this way? That is totally unacceptable. IT's a design flaw no wonder it takes 3 months to replace it ,if it only last a few fires before warping ( probably because they ran out of replacements) That five fire limit is killing them)

I think it time PE steps up to the plate and explains this and what they intend to do about it..

Really these are not Vogelzangs but expensive stoves and one should expect and demand more. Tom what do you have to say you mail ordered quite a few here

if this was a new car, how happy would you be when the paint starts flaking off? The dealer tells you its ok ,it does not effect the way it drives and it is normal for it to do this?

maybe there should be a recall? class action suit?

fishercat

New Member

I agree at least let us know if its ok. I am going to send mine away at the end of the season just to see what they say. Stove is great otherwise and maybe this is something that's normal but at least tell us the story on it. Far as holes in the back the secondary air comes out in one big wave the whole width of the firebox so it doesn't seem like holes to me.

Gunner

New Member

The baffle IS flat, weights close to 30lbs on the summit and spans 20". Basically it is a 20x20x2 box with a secondary air supply at the back. There are 2 rows of air holes across the front and 1 row in the middle font to back were secondary air is delivered.

There is no functional problem with a 1/4 belly to it. The only way burn would be affected is if the baffle was breached and secondary air was coming out somewhere other than the 3 rows of airholes.

There is no functional problem with a 1/4 belly to it. The only way burn would be affected is if the baffle was breached and secondary air was coming out somewhere other than the 3 rows of airholes.

Attachments

webbie

Seasoned Moderator

Well, you can't argue with it still working after 15 years! And the newer one is better even.....

A "box" is certainly many times stronger than a flat piece of steel because of the bends in the end(s) and sides. And it is also cooled by the airflow through it. I'd guess that it is a sound design because Tom would certainly know at this point -and the Omni study had two PE's in it, both of which performed pretty dang well.

There is no excuse for that attitude by the dealer, though. If I was your dealer I would simply tell you this was normal (if it was), and if it was not, I certainly would not make you remove it and send it back somewhere for them to look at it! I would look at it (either in my shop or in your house).....

Telling folks what is normal and what to expect is a BIG part of avoiding problems!

Sounds like a dealer with too much on their minds in mid-season.

A "box" is certainly many times stronger than a flat piece of steel because of the bends in the end(s) and sides. And it is also cooled by the airflow through it. I'd guess that it is a sound design because Tom would certainly know at this point -and the Omni study had two PE's in it, both of which performed pretty dang well.

There is no excuse for that attitude by the dealer, though. If I was your dealer I would simply tell you this was normal (if it was), and if it was not, I certainly would not make you remove it and send it back somewhere for them to look at it! I would look at it (either in my shop or in your house).....

Telling folks what is normal and what to expect is a BIG part of avoiding problems!

Sounds like a dealer with too much on their minds in mid-season.

Attachments

Gunner

New Member

There is no excuse for that attitude by the dealer, though. If I was your dealer I would simply tell you this was normal (if it was), and if it was not, I certainly would not make you remove it and send it back somewhere for them to look at it! I would look at it (either in my shop or in your house).....

Agreed.

A good dealer should know enough about the product line (what is a warranty claim vs what's not) take care of the customer and then deal with the MFG later.

Gunner

New Member

"Firebox of a Pacific Energy certified woodstove after 11 years of use as a primary heat source. Emissions of particulates from this woodstove measured in 1999 were below the EPA certification threshold for new non-catalytic woodstove models."

As you can see the rails that hold the baffle are a little bent at the back...no big deal, there only purpose is to hold the baffle in place and the tabs at the bottom hold the bricks up.

This is not out of the ordinary IMO after years of hard use 24/7. It is not uncommon to rebuild/re-gasket/cement a cast stove every 5-10yrs. Replacing a Cat combuster 5-10yrs as well. Expect some maintanence with a Non-cat too. Combusters can cost $100-200 every 5yrs roughly...if you had to replace the baffle, burn tubes, flame shield, insulation etc every 10yrs in a non cat it would be the same $$ wise....that's the cost of burning.

As you can see the rails that hold the baffle are a little bent at the back...no big deal, there only purpose is to hold the baffle in place and the tabs at the bottom hold the bricks up.

This is not out of the ordinary IMO after years of hard use 24/7. It is not uncommon to rebuild/re-gasket/cement a cast stove every 5-10yrs. Replacing a Cat combuster 5-10yrs as well. Expect some maintanence with a Non-cat too. Combusters can cost $100-200 every 5yrs roughly...if you had to replace the baffle, burn tubes, flame shield, insulation etc every 10yrs in a non cat it would be the same $$ wise....that's the cost of burning.

Attachments

webbie

Seasoned Moderator

Certainly looks like a proven design! What threw me off is "flat piece of steel", when in fact it seems to be a fabricated box assembly.

Isn't it interesting how the dealer response (or even our own) can create friction where there is none! As I said, if I were a dealer, I would simply tell the customer that this is normal behavior (based on my experiences and perhaps talks with the factory) and that as long as it did not go past a certain point it is within spec.

Same thing as enamel stove manufacturers who often say that any chip under a certain size should be touched up.

The vast majority of folks would not even be able to see 1/4" in 20".

Isn't it interesting how the dealer response (or even our own) can create friction where there is none! As I said, if I were a dealer, I would simply tell the customer that this is normal behavior (based on my experiences and perhaps talks with the factory) and that as long as it did not go past a certain point it is within spec.

Same thing as enamel stove manufacturers who often say that any chip under a certain size should be touched up.

The vast majority of folks would not even be able to see 1/4" in 20".

I'm appreciating all of your input, guys. I probably shouldn't have used the term "flat piece of steel." I just meant that the bottom of the baffle assembly was flat when I installed it, but now has a bow to it. From all of your comments, it sounds like this isn't going to affect the burn at all, though I will say that on the first baffle, I was getting secondary burn out from the back of the baffle due to the warpage. But I suppose secondary burn is secondary burn....

In terms of noticing it at all, I can only say that I'm obsessive by nature!

In terms of noticing it at all, I can only say that I'm obsessive by nature!

webbie

Seasoned Moderator

Well, not totally obsessive! I would guess that in shipping or handling, the rear of your first baffle (looks like it is gasketed) may have not sealed tight against the manifold that brings in the air - Tom (chimneysweep) can confirm how tight that connection is supposed to be.

Total guess, of course!

Total guess, of course!

E

elkimmeg

Guest

Can an engineer PE engineer explain it is supposed to warp? why not print that in the manual? or dealers warn up front.

Your bafflet is going to warp but does not effect the gasket of secondary burn

the paint on you new car is going to flake off but to to get concerned it does not effect it driving don't worry after the first 100 miles bring it back we will ship it to the manufactures and you will be without a car for 3 months while the paint is being replaced .

If that happening to me on a new stove and that's the answer I got it would not sit well. There is a design flaw what is acceptable warpage 1/4" in the first 5 fires ?

at what point does the gasket seal become effected? is it ok up to 1/2" bow

Your bafflet is going to warp but does not effect the gasket of secondary burn

the paint on you new car is going to flake off but to to get concerned it does not effect it driving don't worry after the first 100 miles bring it back we will ship it to the manufactures and you will be without a car for 3 months while the paint is being replaced .

If that happening to me on a new stove and that's the answer I got it would not sit well. There is a design flaw what is acceptable warpage 1/4" in the first 5 fires ?

at what point does the gasket seal become effected? is it ok up to 1/2" bow

Gunner

New Member

20 odd years of the same design, #1 stove in Canada, and Elkimeg from hearth.com thinks there is a design flaw after admitting he has never even seen a PE stove.

Stove MFG's have no obligation to explain anything to you or anyone else on hearth.com

The original poster had his baffle replaced because of 1/4 of sag, there was no mention of how long it took. I think the fact that it was replaced being only 1/4 off speaks well for the company...many would not. Some companies ask you if you know somebody who welds when your insert collapses on itself.

Fishercat who called a dealer (sounds like it was not where he puchased it) was told of sending it in and the long delay. This may be true or it may be over the phone speculation from a dealer who does not want to bother with someone who didn't buy from them...especially during the busy fall season.

********************** :lol: ***************************

Elker, take two of these and call me in the morning.

I think it time PE steps up to the plate and explains this and what they intend to do about it..

Stove MFG's have no obligation to explain anything to you or anyone else on hearth.com

no wonder it takes 3 months to replace it ,if it only last a few fires before warping ( probably because they ran out of replacements) That five fire limit is killing them)

The original poster had his baffle replaced because of 1/4 of sag, there was no mention of how long it took. I think the fact that it was replaced being only 1/4 off speaks well for the company...many would not. Some companies ask you if you know somebody who welds when your insert collapses on itself.

Fishercat who called a dealer (sounds like it was not where he puchased it) was told of sending it in and the long delay. This may be true or it may be over the phone speculation from a dealer who does not want to bother with someone who didn't buy from them...especially during the busy fall season.

maybe there should be a recall? class action suit?/

********************** :lol: ***************************

Elker, take two of these and call me in the morning.

thechimneysweep

Minister of Fire

I hadn't really ever given the belly sag ( a more appropriate term, I think, than "warping", or at least better-sounding, no?) much thought, as mine has been that way for so long and it still works fine. But the forum, as usual, got me thinking about it, so I asked Howard, our Master Sweep, what he sees in the field.

Turns out the belly sag is a common phenomenon, more pronounced in the older, mild steel baffle boxes but still sometimes evident in the newer stainless boxes after a few years. I view it as a non event, performance-wise, as there's no way that slight bulge could affect the secondary burn. Plus, we've got hundreds of PE's out in the field that are 20+ years old, and have only replaced maybe a handful of baffle boxes in that period.

The secondary flames along the back of the baffle box described in one post above don't sound right, though. I'd say check your baffle gasket (the little rectangular gasket that seals the baffle box onto the secondary air supply tube), and replace it if necessary. If the new gasket doesn't solve the problem, PM me about it and I'll process a warranty claim for you. That same day.

Turns out the belly sag is a common phenomenon, more pronounced in the older, mild steel baffle boxes but still sometimes evident in the newer stainless boxes after a few years. I view it as a non event, performance-wise, as there's no way that slight bulge could affect the secondary burn. Plus, we've got hundreds of PE's out in the field that are 20+ years old, and have only replaced maybe a handful of baffle boxes in that period.

The secondary flames along the back of the baffle box described in one post above don't sound right, though. I'd say check your baffle gasket (the little rectangular gasket that seals the baffle box onto the secondary air supply tube), and replace it if necessary. If the new gasket doesn't solve the problem, PM me about it and I'll process a warranty claim for you. That same day.

webbie

Seasoned Moderator

Thread closed - I think the problem (if there was one) is evident and solved. If others have this problem, or if the original poster does not get taken care of, we can start another.

- Status

- Not open for further replies.

Similar threads

- Replies

- 0

- Views

- 492

- Replies

- 1

- Views

- 521

- Replies

- 26

- Views

- 2K

- Replies

- 6

- Views

- 1K