Hello

I picked up a dead Englander 25-PDV manufacturer's date 03/2005.

At 375 lbs it is a heavy one!!

So after seeing the heat fan settings of 6 - 6 the stove shut down with an E-2 and an E1 error.

See 1st and 2nd pics

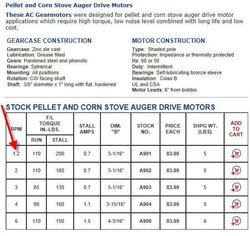

Then I checked all the motors (Auger & Blower) with the AC test cord and they ran.

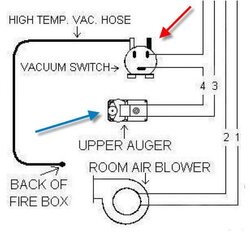

So I then jumped out the vacuum switch connected to the exhaust since E1 means exhaust air flow error. See 3rd pic

Sure enough, the stove went thru the startup cycle and ran for an hour or so.

See 4th pic

Then I noticed the slightly noisy bottom auger slowing down and not feeding many pellets until the fire almost went out. See 5th pic

Then I shut it down.

So doe this indicate the bottom auger may be failing or need lubrication? If so how?

Thanks

I picked up a dead Englander 25-PDV manufacturer's date 03/2005.

At 375 lbs it is a heavy one!!

So after seeing the heat fan settings of 6 - 6 the stove shut down with an E-2 and an E1 error.

See 1st and 2nd pics

Then I checked all the motors (Auger & Blower) with the AC test cord and they ran.

So I then jumped out the vacuum switch connected to the exhaust since E1 means exhaust air flow error. See 3rd pic

Sure enough, the stove went thru the startup cycle and ran for an hour or so.

See 4th pic

Then I noticed the slightly noisy bottom auger slowing down and not feeding many pellets until the fire almost went out. See 5th pic

Then I shut it down.

So doe this indicate the bottom auger may be failing or need lubrication? If so how?

Thanks