I bought a used EBW-300 , then had Econoburn essentially rebuild it to like new condition. They replaced the whole back of the boiler , completely new heat exchanger, then went over the entire boiler. The previous owner had the boiler plumbed to 2”( the min pipe size), when I got the boiler there was no loop pump . What I would like to know is, what is the make and model of the pump that comes from the factory? Also what size pipe are you owners using for your loop and piping to and from your storage? Mark

Need info from Econoburn EBW-300 users

- Thread starter mark cline

- Start date

-

Active since 1995, Hearth.com is THE place on the internet for free information and advice about wood stoves, pellet stoves and other energy saving equipment.

We strive to provide opinions, articles, discussions and history related to Hearth Products and in a more general sense, energy issues.

We promote the EFFICIENT, RESPONSIBLE, CLEAN and SAFE use of all fuels, whether renewable or fossil. -

Super Cedar firestarters 30% discount Use code Hearth2024 Click here

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

I had called Econoburn, and Dale says he has the same boiler and uses the Grundfos UPS15-58FC running on high speed. The largest flange size that you get with is pump is 1 1/2”, why would you use this pump if your min pipe size is 2 inch? If you went with the factory recommendation of 2 1/2” , going to 1 1/2” you would restrict your flow , right? The UPS15-58FC has a max 17 gpm and 19.5 ft head , somehow I don’t feel this is enough flow , my son uses this pump on his 80000 BTU wood boiler. How about some information from non Econoburn boiler users ? Thanks

Hi

Thats what is on my 200 for the protection loop.

The neck down for the loop application is fine because all you are doing is circulating water in the boiler

My main pump to storage is on 1 1/2 pipe and run a bigger pump on that pipe.

Thats what is on my 200 for the protection loop.

The neck down for the loop application is fine because all you are doing is circulating water in the boiler

My main pump to storage is on 1 1/2 pipe and run a bigger pump on that pipe.

I guess the problem I’m having is the min loop size is 2” then you neck down to 1 1/2” then back up to 2” . I would think you would starve the boiler , right? Or would your aqua stat open then pull more water through the boiler by your larger pump. What size is your circulating pump? With my 300 , I’m hesitant to neck it down to 1 1/2” when the manual calls for 2” min loop.

maple1

Minister of Fire

My 140k btu boiler has 1-1/4" for all near boiler and to/from storage piping. Loading unit has a Grundfoss 15-58 3 speed. No issues. It's on low speed 95% of the time. I sometimes bump it up to speed 2 if too much flow is going to zones vs to storage. For whatever that's worth. Kinda basic - if your boiler is bouncing off high temp limit a lot, it's under flowing. If not, it's good. With storage, that is.

I’m looking at going with the 2” for the loop and plumbing in 2 ups15-58fc pumps , maybe overkill , but I’d rather be over than under.

Next question is, what is the best way to regulate 150 degree into the return ? Mixing valve thermobloc , or some sort of temp sensored variable speed pump?

Next question is, what is the best way to regulate 150 degree into the return ? Mixing valve thermobloc , or some sort of temp sensored variable speed pump?

maple1

Minister of Fire

Have you observed conditions that make you think what Dale told you isn't enough? If I'm understanding right, this is on a bypass loop? Just pumping from top of boiler to bottom? I'm not fathoming how a 3 speed 15-58 is not enough for that. Maybe I misunderstood something.

Also, on the last point -'best' is measured differently by different preferences and priorities. The simplest and easiest is use a loading unit. Thermostatic and has circulator built in. Mine has been holding a constant 140 return through every burn since the fall of 2012.

Also, on the last point -'best' is measured differently by different preferences and priorities. The simplest and easiest is use a loading unit. Thermostatic and has circulator built in. Mine has been holding a constant 140 return through every burn since the fall of 2012.

I have not put any pipe together yet. I’m in the planning stage , ordering pipe , fittings etc. after reading through the installation manual , it says min loop size is 2” . I believe what Dale says works , he uses the pump on his 300. Just the fact that it states 2” min pipe , going through a 11/2” pump ♂️.

Please expand on the loading unit. What device are you using to keep the return at 140F? This is what I would like to use , but then again , from my storage return to the boiler 2” pipe to 1 1/4” .

Please expand on the loading unit. What device are you using to keep the return at 140F? This is what I would like to use , but then again , from my storage return to the boiler 2” pipe to 1 1/4” .

Attachments

maple1

Minister of Fire

Google 'LK810'. Some site advertisers sell them, click their banner ads. Mine came from Smokeless Heat.

The near boiler pump loop is an option to the loading valve that keeps your return at 140 degrees or what ever you set.I don't use on on mine.

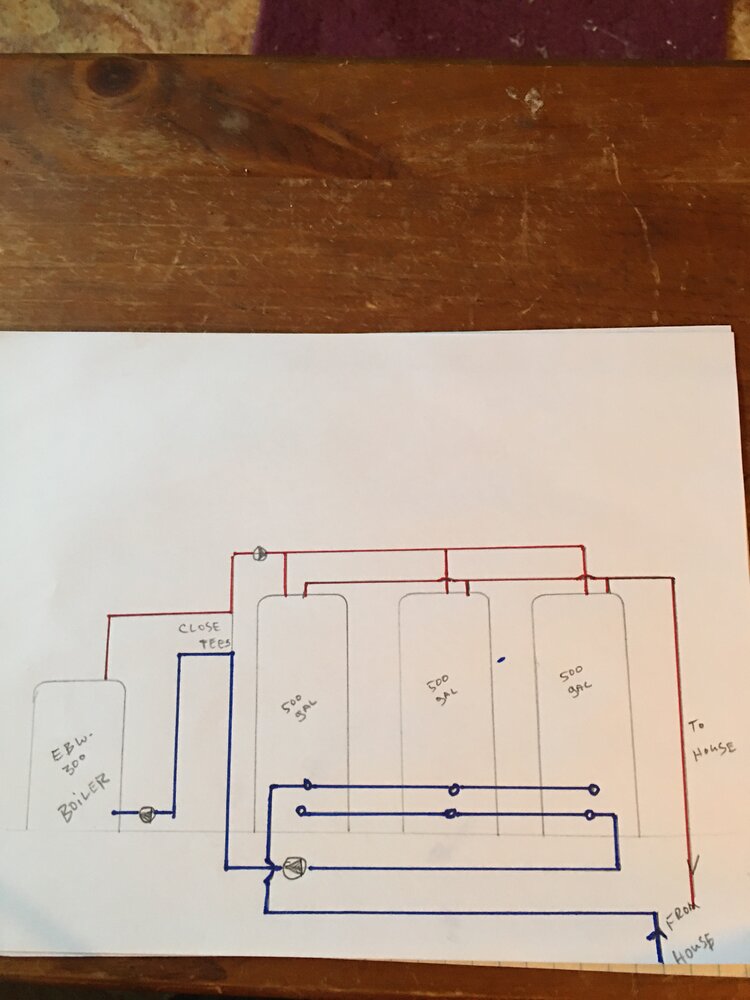

Here is a drawing of my boiler and storage tanks

Feel free to comment . The 3 pumps are UPS15-58FC at 1 1/2” the protection loop and secondary loop to and from storage is 2” steel black pipe . All piping to the house and return are 1 1/2” pex. I need to finalize this project and get going on the installation. Thanks

Feel free to comment . The 3 pumps are UPS15-58FC at 1 1/2” the protection loop and secondary loop to and from storage is 2” steel black pipe . All piping to the house and return are 1 1/2” pex. I need to finalize this project and get going on the installation. Thanks

maple1

Minister of Fire

I could be missing something but I'm not seeing how that functions as boiler protection.

Edit: hard to tell though without knowing controls.

Edit: hard to tell though without knowing controls.

I’m adding as suggestions come in . The boiler starts the protection pump , when it hits 150 , the circulator pump comes on . A thermobloc pump or the 140 F thermomix mixing valve for the boiler return and outdoor reset is in the plans. Are the close spaced T’s good to incorporate into the plans. I have read so much that my head spins , I end up with more questions than answers.

maple1

Minister of Fire

Are there any piping schematics in Econoburn literature? I like simple. For me that would be one pipe out of top of boiler to the top of your storage. Another from bottom of storage back to bottom of boiler. With them connected with a short bypass pipe close to the boiler, with a thermostatic valve at/as the bottom T of that bypass, and one circ between the T and the bottom of boiler. Pumping/pulling through to the thermo T into the boiler. (If you dont use a loading unit). Circ starts and runs whenever boiler is up to temp, stops running when fire goes out and top of boiler drops below set point. Sole purpose of all that is move heat away from boiler. Then loads just pull from top of storage, return to bottom. Could be thru same pipe as boiler. If you dont have all those holes in your tanks already, you only need 2 in each - one at top, one at bottom. I see you have reverse return shown - that is a good design point.

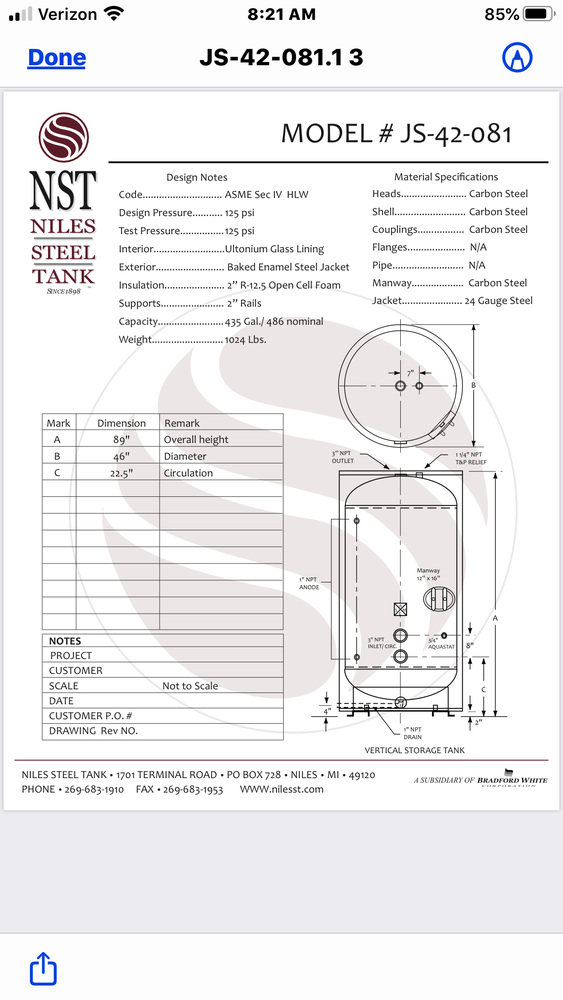

The tanks are water storage tanks , there is a schematic of the tanks in my first post. I was thinking of a separate piping system for the boiler to storage and storage to the house through 100 ft of underground pex. The tanks may not be ideal but the size and deal on the 3 was something I couldn’t pass up. The house and heated basement are about 3500 sq ft. all radiant floor heat.

Another problem I was up against is loading the storage equally between the 3 tanks and then pulling water out of the 3 equally. And again, the boiler is 2.5 “ and tanks at 3”, so pump size and the 3 pumps, I feel are needed. The loading unit and thermomix Valve are 1 1/4” , a problem? I don’t know.

Another problem I was up against is loading the storage equally between the 3 tanks and then pulling water out of the 3 equally. And again, the boiler is 2.5 “ and tanks at 3”, so pump size and the 3 pumps, I feel are needed. The loading unit and thermomix Valve are 1 1/4” , a problem? I don’t know.

maple1

Minister of Fire

Bigger pipe is definitely a plus for gravity flow heat dump situations. I don't think necking down to 1-1/4 for the short length of a T and circ will be a big problem. I have read of some who plumb a second circ into another short bypass loop that bypasses the main thermo T and circ, to add more flow from bottom of storage directly into bottom of boiler. Controlled to only come on when temps get up to high limit (boiler getting too hot).

I like the second circulator pump and the short bypass. When this is fired up , it’s going to take some time to bring the tanks up to temp. before I start to heat the basement floor and house , so I’m not concerned about running a separate supply and return back to the tanks . Do you feel that the supply and return from the boiler and house would equally fill and empty the tanks. That’s my biggest concern.

I would plumb it as Maple 1 has suggested, the simple thermostatic valve between the supply and return. It's essentially the same as an automotive thermostat. This is how European boilers are typically plumbed. Less to fail than another circ. in my opinion. I've been satisfied with my Danfoss unit. Return temp protection is essential, the lack of it may be the reason yours required a rebuild.

With respect to pipe diameter bear in mind that major friction losses come from the length of pipe (5' of slightly smaller pipe has much less impact than having it for the entire say 200' loop). Minor losses come from fittings. The overall head loss is what the circ. needs to overcome and still provide the needed flow to move the required BTU's.

You're on the right track - best to plan ahead and do your best to get it right the first time. Good luck.

With respect to pipe diameter bear in mind that major friction losses come from the length of pipe (5' of slightly smaller pipe has much less impact than having it for the entire say 200' loop). Minor losses come from fittings. The overall head loss is what the circ. needs to overcome and still provide the needed flow to move the required BTU's.

You're on the right track - best to plan ahead and do your best to get it right the first time. Good luck.

maple1

Minister of Fire

I would plumb it as Maple 1 has suggested, the simple thermostatic valve between the supply and return. It's essentially the same as an automotive thermostat. This is how European boilers are typically plumbed. Less to fail than another circ. in my opinion. I've been satisfied with my Danfoss unit. Return temp protection is essential, the lack of it may be the reason yours required a rebuild.

With respect to pipe diameter bear in mind that major friction losses come from the length of pipe (5' of slightly smaller pipe has much less impact than having it for the entire say 200' loop). Minor losses come from fittings. The overall head loss is what the circ. needs to overcome and still provide the needed flow to move the required BTU's.

You're on the right track - best to plan ahead and do your best to get it right the first time. Good luck.

Echo this, and I forgot about Danfoss. I think they have bigger ones if your still worried about flows. Although I dont think you need too. You could always plumb in 2 Ts with valved stubs on them, for possible later use if needed for a short bypass loop and second circ. Also if going Danfoss, plumb in a ball valve on the main bypass leg, above the Danfoss, both for isolating water if you have to service it (well, should be iso valves on all legs actually), and also for possible use in throttling bypass flow some if needed. Some Danfoss users have needed to do that, for reasons I never did get to fully understanding.

maple1

Minister of Fire

I like the second circulator pump and the short bypass. When this is fired up , it’s going to take some time to bring the tanks up to temp. before I start to heat the basement floor and house , so I’m not concerned about running a separate supply and return back to the tanks . Do you feel that the supply and return from the boiler and house would equally fill and empty the tanks. That’s my biggest concern.

You should be able to start heating your house pretty much as soon as the boiler starts sending to storage. Loads pull from same place your boiler supplies (top of storage). And if you mean will all 3 tanks fill and draw at the same rate (thermocline at equal heights?), they should using reverse return like your diagram shows. But if you needed to, you could also do some throttling with iso valves at the tank ports (iso valves should be there too) to help balance things. Get some temp gauges for each tank, measuring at 2 or 3 equal height points on each tank.

I like the thermostatic valve arrangement, was considering using 2 going into the return of the boiler . My thinking is 2 at 1 1/4” would give me more than enough return from my almost 1500 gallons of storage. This is not a redo , this is a new installation for me. Could have been the problem for the previous owner along with poor quality wood. I bought a used Econoburn 300k boiler and had Econoburn, essentially rebuilt it to like new condition . I looked at Danfoss and they have a 2” . Hydronics, what is the model number of your Danfoss valve, is there a separate actuator? I don’t think they were thermostatic like the Caleffi valves.

maple1

Minister of Fire

The only place that I could put in a thermowell is where the anode rods would go plus the hole for a 3/4” aquastat

Similar threads

- Replies

- 9

- Views

- 3K

- Replies

- 6

- Views

- 693

- Replies

- 41

- Views

- 5K

- Replies

- 0

- Views

- 1K