M

MasterMech

Guest

The time has come!

Awhile back I aquired (freebie!) a MS460 that got in a fight with an F550 and lost. The saw was barely a week old from what I understand. It's a total loss except for the cylinder, piston, crank, clutch and a few small items.

The saw was barely a week old from what I understand. It's a total loss except for the cylinder, piston, crank, clutch and a few small items.

I bought another 460 from flea-bay with a toasted Piston/Cyl but with what looks to be a good chassis to build on. The plan is to carry over as many engine parts as possible, bearings, crank, piston/cyl to this saw and replace the AV buffers and clutch along with other good parts from the donor unit as well. I have new crank seals and gaskets for the build already.

I am undecided as to keep the finished product or flip it. If I decide to sell it, I wonder how much the broken fin on the donor cylinder will affect value of the finished saw vs. just doing an aftermarket cylinder? I've yet to disassemble the receiving saw so the actual condition of that cylinder is unknown. Power of the OEM Cyl vs. Aftermarket? I welcome everybody's experiences here.

The loser......

The cylinder is like new except for that damn chip.

Next step will be complete disassembly to salvage engine parts.

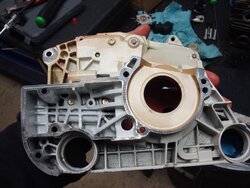

The willing recipient.

Awhile back I aquired (freebie!) a MS460 that got in a fight with an F550 and lost.

The saw was barely a week old from what I understand. It's a total loss except for the cylinder, piston, crank, clutch and a few small items.

The saw was barely a week old from what I understand. It's a total loss except for the cylinder, piston, crank, clutch and a few small items.I bought another 460 from flea-bay with a toasted Piston/Cyl but with what looks to be a good chassis to build on. The plan is to carry over as many engine parts as possible, bearings, crank, piston/cyl to this saw and replace the AV buffers and clutch along with other good parts from the donor unit as well. I have new crank seals and gaskets for the build already.

I am undecided as to keep the finished product or flip it. If I decide to sell it, I wonder how much the broken fin on the donor cylinder will affect value of the finished saw vs. just doing an aftermarket cylinder? I've yet to disassemble the receiving saw so the actual condition of that cylinder is unknown. Power of the OEM Cyl vs. Aftermarket? I welcome everybody's experiences here.

The loser......

The cylinder is like new except for that damn chip.

Next step will be complete disassembly to salvage engine parts.

The willing recipient.

I've done many carry-over rebuilds (even re-using gaskets when possible) with great results. The OEM piston/cylinder will be fine, why not do a match-port while you have it torn down? Also a dual port muffler! Might as well, both are very easy mods to that saw! If I was closer I'd help ya with the porting, brother.

I've done many carry-over rebuilds (even re-using gaskets when possible) with great results. The OEM piston/cylinder will be fine, why not do a match-port while you have it torn down? Also a dual port muffler! Might as well, both are very easy mods to that saw! If I was closer I'd help ya with the porting, brother. ) through a workbench made from 8x's and a heavy 2x top. He said he wanted it about 18" narrower than it was. That made a lot of guys in the shop

) through a workbench made from 8x's and a heavy 2x top. He said he wanted it about 18" narrower than it was. That made a lot of guys in the shop  ! I certainly had everybody's attention!

! I certainly had everybody's attention!