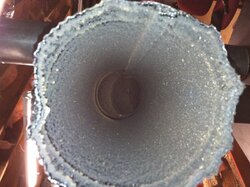

See the dents on the end of the pipe? Those dents correspond with the dark spots. Those are all air leaks.

That my friend, isn't helping any either.

A sealed system (whether its a liner or not), good fuel, and good burning habits (good flue temps, burning in full cycles when possible, getting up to temp quickly, etc) are all critical to keeping.your flue as clean and safe as possible.

On the connection from my stove to the first section of pipe, I sealed there, then also at the thimble, and I wrapped every joint with High temp foil tape (I have double wall. Wouldn't recommend that for your single wall, but cement wont hurt). It looks goofy, but I know I am doing everything I can to keep the gases as Hot as possible on there way up the flue

Click to enlarge

View attachment 97114

) crazy enough to self induce a chimney fire before installing his liner!

When I installed my liner, I thought about it.....but not enough "swagger"

When I installed my liner, I thought about it.....but not enough "swagger"