So here we go. Thanks to all the advice on this forum, this stove will be throwing heat by Saturday evening. The stove arrived yesterday via LTL carrier. Box looked good, all set. I open the stove to find a cracked fire brick. I call Englander and within minutes they have one on the way to me. My gasket looked a little "rough" at one end and he explained it may be a little fraying as they are cut to length when installed and it should be fine. I felt around the rough area and it seems to be in decent shape.

I have to say that I was impressed with their customer service and the guy on the phone was very helpful....

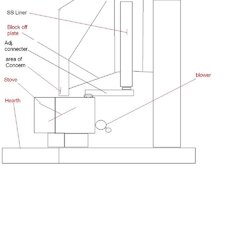

So now I have a stove, have my liner, top plate, appliance adapter, raincap, etc. I am ready to do this.

I was so excited I had to build a nice fire outside, which Englander said would be fine and a good place to break in the stove.

I couldn't really shut the door all the way because it would put the fire out, but I assume that is because there was no chimney pipe to create draft??? Either way I was able to shut it down, sort of, and I really think I was able to get secondaries...

I am not sure of what secondaries are supposed to look like but here is what I saw, a lazy flame and the bars at the top of the unit with the holes in them (similar to a bbq burner) looked as if they were connected to propane and was pushing flames out...is that secondary combustion???

Anyway, thanks everyone for the help and here are some pics...I will update this thread as the install progresses..

I have to say that I was impressed with their customer service and the guy on the phone was very helpful....

So now I have a stove, have my liner, top plate, appliance adapter, raincap, etc. I am ready to do this.

I was so excited I had to build a nice fire outside, which Englander said would be fine and a good place to break in the stove.

I couldn't really shut the door all the way because it would put the fire out, but I assume that is because there was no chimney pipe to create draft??? Either way I was able to shut it down, sort of, and I really think I was able to get secondaries...

I am not sure of what secondaries are supposed to look like but here is what I saw, a lazy flame and the bars at the top of the unit with the holes in them (similar to a bbq burner) looked as if they were connected to propane and was pushing flames out...is that secondary combustion???

Anyway, thanks everyone for the help and here are some pics...I will update this thread as the install progresses..

! In the next few posts Ill detail what I did and then I have a few questions for the pro's.....Again, a big thanks to everyone on this forum who has helped directly or posted questions of their own that have helped. I hope doing this install I might be able to help someone else along with what I have learned....

! In the next few posts Ill detail what I did and then I have a few questions for the pro's.....Again, a big thanks to everyone on this forum who has helped directly or posted questions of their own that have helped. I hope doing this install I might be able to help someone else along with what I have learned....