stoveguy2esw

Minister of Fire

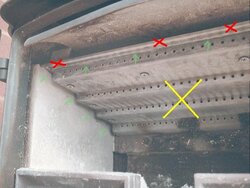

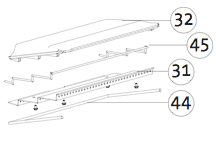

ok , so its not there all the time, sholdnt be an issue then, didnt know if you had that consistantly, the secondaries leave a pattern where the flame paths run against the plate , just looked like they werent as clear there, might even change from fire to fire depending on how wood is arranged, i get it now, kool