I have already used this forum for getting answers to my questions on firewood, now I've got a pretty good stack of wood cut, split and stacked.

See the pics for more info on my setup. "Peacock" wood stove installed by previous owner more than 16 years ago. ID tag on back was mostly painted over but I think I can read this much "------ Stove Works", "------, Michigan". He installed it in a basement he dug out *underneath* our 1-story house (1300 ft2). Basement is partially finished and dry.

We used the stove for fun a few times when we first moved in about 16 years ago. But until last winter's snow storm, we had hardly used it at all. But now I'm out of a good paying job, closer to retirement age and wanting to save on heating cost through the Indiana winter. I would like to use it to supplement our natural gas furnace and save maybe 50% of heating cost.

I used the stove for maybe 2 days last winter and my wife complained of the smell of smoke even upstairs on the main floor... it even gave her headaches (although it did not bother me.)

1) I presume this "peacock" stove a pre-EPA model, correct?

2) I understand the knob on the door is the main vent to control air intake. But what is the circular dial on top with a white knob handle for... another kind of vent?

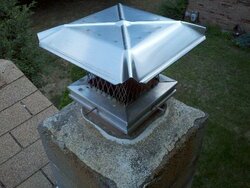

3) Is the chimney setup adequate or should I be looking into getting a metal liner installed inside the 7" square clay liner? (The inside of the clay tile liner seems relatively clean to me. And I can't afford to put a lot of money into this setup.)

4) Perhaps this is the most important... as I said my wife may put a halt to my idea of wood burning unless I can solve this. Is there a way to minimize (or eliminate) most of the smell of smoke and tar? ... Is there gasket material that would work around the doorway and pipe fittings to block the escape of fumes? Also is there a way to keep a backdraft from coming back from the chimney into the house when the stove isn't burning?

I have so many more questions but maybe this will suffice for now.

Thx for any help.

See the pics for more info on my setup. "Peacock" wood stove installed by previous owner more than 16 years ago. ID tag on back was mostly painted over but I think I can read this much "------ Stove Works", "------, Michigan". He installed it in a basement he dug out *underneath* our 1-story house (1300 ft2). Basement is partially finished and dry.

We used the stove for fun a few times when we first moved in about 16 years ago. But until last winter's snow storm, we had hardly used it at all. But now I'm out of a good paying job, closer to retirement age and wanting to save on heating cost through the Indiana winter. I would like to use it to supplement our natural gas furnace and save maybe 50% of heating cost.

I used the stove for maybe 2 days last winter and my wife complained of the smell of smoke even upstairs on the main floor... it even gave her headaches (although it did not bother me.)

1) I presume this "peacock" stove a pre-EPA model, correct?

2) I understand the knob on the door is the main vent to control air intake. But what is the circular dial on top with a white knob handle for... another kind of vent?

3) Is the chimney setup adequate or should I be looking into getting a metal liner installed inside the 7" square clay liner? (The inside of the clay tile liner seems relatively clean to me. And I can't afford to put a lot of money into this setup.)

4) Perhaps this is the most important... as I said my wife may put a halt to my idea of wood burning unless I can solve this. Is there a way to minimize (or eliminate) most of the smell of smoke and tar? ... Is there gasket material that would work around the doorway and pipe fittings to block the escape of fumes? Also is there a way to keep a backdraft from coming back from the chimney into the house when the stove isn't burning?

I have so many more questions but maybe this will suffice for now.

Thx for any help.

Attachments

-

2011-07-29_16-17-49_576.jpg40.8 KB · Views: 1,488

2011-07-29_16-17-49_576.jpg40.8 KB · Views: 1,488 -

2011-07-30_13-14-23_593.jpg51.5 KB · Views: 1,551

2011-07-30_13-14-23_593.jpg51.5 KB · Views: 1,551 -

2011-07-29_16-37-29_132.jpg34.1 KB · Views: 2,811

2011-07-29_16-37-29_132.jpg34.1 KB · Views: 2,811 -

2011-07-29_16-38-34_401.jpg36.2 KB · Views: 2,463

2011-07-29_16-38-34_401.jpg36.2 KB · Views: 2,463 -

2011-07-29_16-38-48_830.jpg38.9 KB · Views: 1,553

2011-07-29_16-38-48_830.jpg38.9 KB · Views: 1,553 -

2011-07-30_13-13-22_93.jpg37.1 KB · Views: 1,502

2011-07-30_13-13-22_93.jpg37.1 KB · Views: 1,502