Lorde

New Member

Alright so inspection passed yesterday. I did two small break in fires yesterday afternoon and night.

First real burn tonight. Set kindling and newspaper, burned to coals in about 20min at wide open. Placed two small splits on top and burned down to coals again at wide open in 20-30 minutes. Added three medium splits and let rip at wide open for a few minutes until stovetop hit about 475 then closed damper.

After cat probe rose to about 900 I started cutting back air. I cut it back fully at about 1100 and it back puffed so I opened it a tiny bit. It ran up to 1300 and I cut it back all the way.

Had some dancing flames and cat ran up to 1440 then hung out at 1300 for bit then very slowly dropped, down to 1150 now.

Sorry for vague timeline I got thirsty tonight.

Seems to be working pretty much as designed. Nice to have all the info ahead of time from this group so thank you.

Edit: STT stabilized at like 650 on infrared thermometer just behind the griddle for most of the time. This is with air cut all the way back, Is that ok?

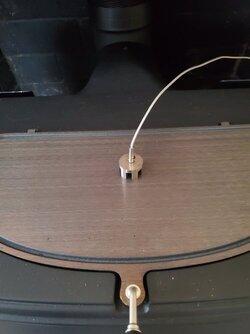

Another Edit: Infrared thermometer readings are in question I just got 114deg on my forehead. I have a magnetic type K thermocouple that I need to modify to work with the Auber I'll do that tomorrow to see what the real SST temps are.

Last edit: I set up the connector on the magnetic thermocouple. When cat was down to about 950 center of griddle was 450.

First real burn tonight. Set kindling and newspaper, burned to coals in about 20min at wide open. Placed two small splits on top and burned down to coals again at wide open in 20-30 minutes. Added three medium splits and let rip at wide open for a few minutes until stovetop hit about 475 then closed damper.

After cat probe rose to about 900 I started cutting back air. I cut it back fully at about 1100 and it back puffed so I opened it a tiny bit. It ran up to 1300 and I cut it back all the way.

Had some dancing flames and cat ran up to 1440 then hung out at 1300 for bit then very slowly dropped, down to 1150 now.

Sorry for vague timeline I got thirsty tonight.

Seems to be working pretty much as designed. Nice to have all the info ahead of time from this group so thank you.

Edit: STT stabilized at like 650 on infrared thermometer just behind the griddle for most of the time. This is with air cut all the way back, Is that ok?

Another Edit: Infrared thermometer readings are in question I just got 114deg on my forehead. I have a magnetic type K thermocouple that I need to modify to work with the Auber I'll do that tomorrow to see what the real SST temps are.

Last edit: I set up the connector on the magnetic thermocouple. When cat was down to about 950 center of griddle was 450.

Last edited: