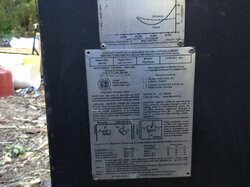

Howdy - first post here.I bought this certified Fisher "The Flame " model last fall on CL. Never knew that Fisher made any certified stoves - this one was made in 1985 by N3 Distributing in Eugene, Oregon. It was about the right size for my home and, having used a Fisher stove for years, I knew they were well built.I installed a couple of water heating boxes in it, each measuring 1 1/2" x 6" x 18" and thermosiphoning together into a 40 gallon water heater.I get tons of hot water which is good, because in the winter, the wood stove is my only source of hot water.The water heating boxes are mounted where the firebricks were on either side of the firebox.

The stove has a sliding plate to close off the flue when recirculating flue gasses for more complete combustion.Above this sliding plate is a round baffle plate with several holes in it, about 1/2" in diameter.

I could tell that the flue pipe , which is about 18 ft. of straight pipe, was building up a fair amount of creosote ever since I began using the stove.Burning dry Madrone and Fir. I figured that this was probably due to the amount of surface area of the water heating boxes creating some condensation ? Periodically I would hear chunks fall down the flue pipe.I tend to close the stove down at night and then open it up in the morning to get the fire going. A few days ago, I banged on the stovepipe a coupe of times and a lot of creosote fell down and began to ignite on top the the flue baffle plate. There is no way for the loose creosote to fall back into the firebox.In no time, the stovepipe was red hot even with the stove closed down.

I am wondering about the idea of removing the baffle plate so that any loose creosote can fall back into the firebox rather than building up on the baffle plate.Any reason not to ? This would make it way easier to clean the flue as well rather than having to remove the pipe from the stove and vacuum it up and all that.

Any thoughts - thanks -Dave

The stove has a sliding plate to close off the flue when recirculating flue gasses for more complete combustion.Above this sliding plate is a round baffle plate with several holes in it, about 1/2" in diameter.

I could tell that the flue pipe , which is about 18 ft. of straight pipe, was building up a fair amount of creosote ever since I began using the stove.Burning dry Madrone and Fir. I figured that this was probably due to the amount of surface area of the water heating boxes creating some condensation ? Periodically I would hear chunks fall down the flue pipe.I tend to close the stove down at night and then open it up in the morning to get the fire going. A few days ago, I banged on the stovepipe a coupe of times and a lot of creosote fell down and began to ignite on top the the flue baffle plate. There is no way for the loose creosote to fall back into the firebox.In no time, the stovepipe was red hot even with the stove closed down.

I am wondering about the idea of removing the baffle plate so that any loose creosote can fall back into the firebox rather than building up on the baffle plate.Any reason not to ? This would make it way easier to clean the flue as well rather than having to remove the pipe from the stove and vacuum it up and all that.

Any thoughts - thanks -Dave