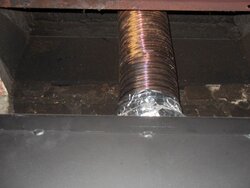

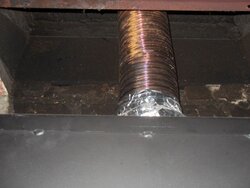

This is my insert - it is a "Flame 1.9-I" made by SBI, and it has a 2.3 cu.ft firebox. She burns well - too well, in fact. I have an interior chimney, the insert is in a formerly double open sided fireplace. There is only one air control (lower right on pic). When it is in the 'fully closed' position, there is still air feeding the firebox through a nickel-sized air hole on the sliding air-control lever. In the past, I have partially covered the hole with a magnet to restrict air flow in order to slow down the rate of burn. But, this solution was not ideal. I spoke to some techs at SBI, and they seem to think that due to my interior 2 story chimney (and the fact that the stove is only a year old, and the gaskets are all good and tight), that my draft is actually TOO good. Has anyone else experienced this problem? Since I still have access to the back of the insert from the back (double-sided fireplace), I was thinking about adding a flue damper just above the stove. There is limited room above the stove, so it would HAVE TO be installed right on the collar itself. It just seems to make sense that if I could reduce the draft a little - that I could control the burn rate better than I can now. Ive included a link to the Flame website as well. What to you guys think?

http://www.flame-intl.com/product.aspx?CategoId=7&Id=457

http://www.flame-intl.com/product.aspx?CategoId=7&Id=457