Hi newbie here. Currently have a Splitfire 18 tonne 2 way splitter run off tractor hydraulics.. Has a 3.5"x 24" cylinder. Run tractor about 1500 rpm so guessing around that 10-12 gpm flow (tractor pump around 20gpm at 2200). Want to split inside a barn so looking to make a hydraulic power pac to run the splitter. Currently have a 5hp leeson TEFC motor @1750 RPM I'd like to use. I'd have to use a couple of right sized pulleys to run a 3600 16gpm 2 stage pump. Think this would work? Other option is to buy a 5hp compressor c face type motor rated at 20-23 amps and mount pump directly to motor. Is either option enough motor to run the pump or should I go to a 11 or 13 gpm pump. I did read somewhere of someone going to make one using a 5 hp 1750 motor running a 28 gpm pump but don't know if this would work. I do want a fast cycle time like I currently have with the splitter run off the tractor (about a 6-8 cycle time). Thanks

Making an electric power pac for tractor splitter

- Thread starter AndyMoore

- Start date

-

Active since 1995, Hearth.com is THE place on the internet for free information and advice about wood stoves, pellet stoves and other energy saving equipment.

We strive to provide opinions, articles, discussions and history related to Hearth Products and in a more general sense, energy issues.

We promote the EFFICIENT, RESPONSIBLE, CLEAN and SAFE use of all fuels, whether renewable or fossil. -

Super Cedar firestarters 30% discount Use code Hearth2024 Click here

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

ericm979

Feeling the Heat

Keep in mind that the two stage pump is 16 gpm (or whatever its rated at) but at a maximum of 600 psi (or whatever the cut over relief is set at). Then it's more like 2-3 gpm up to the 3500 psi or whatever the relief is set for).

So you don't need the power to push 16 gpm at 3500 psi. 600 psi @ 16 gpm needs 5.8 hp, 3500 psi @ 2 gpm needs 4 hp.

With a 3.5" cylinder you can go less than 16 gpm and still get a decent cycle time. A 3600 rpm motor would let you eliminate the pulley system and drive the pump directly.

You'll need a tank large enough for the fluid to cool some.

So you don't need the power to push 16 gpm at 3500 psi. 600 psi @ 16 gpm needs 5.8 hp, 3500 psi @ 2 gpm needs 4 hp.

With a 3.5" cylinder you can go less than 16 gpm and still get a decent cycle time. A 3600 rpm motor would let you eliminate the pulley system and drive the pump directly.

You'll need a tank large enough for the fluid to cool some.

Keep in mind that the two stage pump is 16 gpm (or whatever its rated at) but at a maximum of 600 psi (or whatever the cut over relief is set at). Then it's more like 2-3 gpm up to the 3500 psi or whatever the relief is set for).

So you don't need the power to push 16 gpm at 3500 psi. 600 psi @ 16 gpm needs 5.8 hp, 3500 psi @ 2 gpm needs 4 hp.

With a 3.5" cylinder you can go less than 16 gpm and still get a decent cycle time. A 3600 rpm motor would let you eliminate the pulley system and drive the pump directly.

You'll need a tank large enough for the fluid to cool some.

How about 2 long extension hoses with quick disconnects. Run the tractor outside, split inside.

my tractor has regen on it. Running at low rpm (which is all I need to get a fast cycle time) puts it into regen alot faster because of the pdf filter. Over time the filter becomes plugged and they are very expensive to replace. And I really don't want to run the tractor at 1800-2000 rpm eitherHow about 2 long extension hoses with quick disconnects. Run the tractor outside, split inside.

my tractor has regen on it. Running at low rpm (which is all I need to get a fast cycle time) puts it into regen alot faster because of the pdf filter. Over time the filter becomes plugged and they are very expensive to replace. And I really don't want to run the tractor at 1800-2000 rpm either

I already have the 5 hp 1725 motor. It is a much heavier built motor than some of the compressor type motors I saw with c face mount. I can go down to a 13gpm 2 stage pumpKeep in mind that the two stage pump is 16 gpm (or whatever its rated at) but at a maximum of 600 psi (or whatever the cut over relief is set at). Then it's more like 2-3 gpm up to the 3500 psi or whatever the relief is set for).

So you don't need the power to push 16 gpm at 3500 psi. 600 psi @ 16 gpm needs 5.8 hp, 3500 psi @ 2 gpm needs 4 hp.

With a 3.5" cylinder you can go less than 16 gpm and still get a decent cycle time. A 3600 rpm motor would let you eliminate the pulley system and drive the pump directly.

You'll need a tank large enough for the fluid to cool some.

I am no expert but I think the belt and pulley system may be difficult to guard and use safely. I run a 4x18 inch cylinder. forgot the shaft size, and 11gpm pump off a 2 hp ,220, 3450 rpm motor. The motor is a C face and connects to the pump directly through an adapter. It is not fast but there is very little that gives it difficulty. I would say that is the best way to go. If starting with a new ,or maybe better, a used motor stay with 3450 rpm. A five hp seems like it would be plenty for the 16 gpm pump

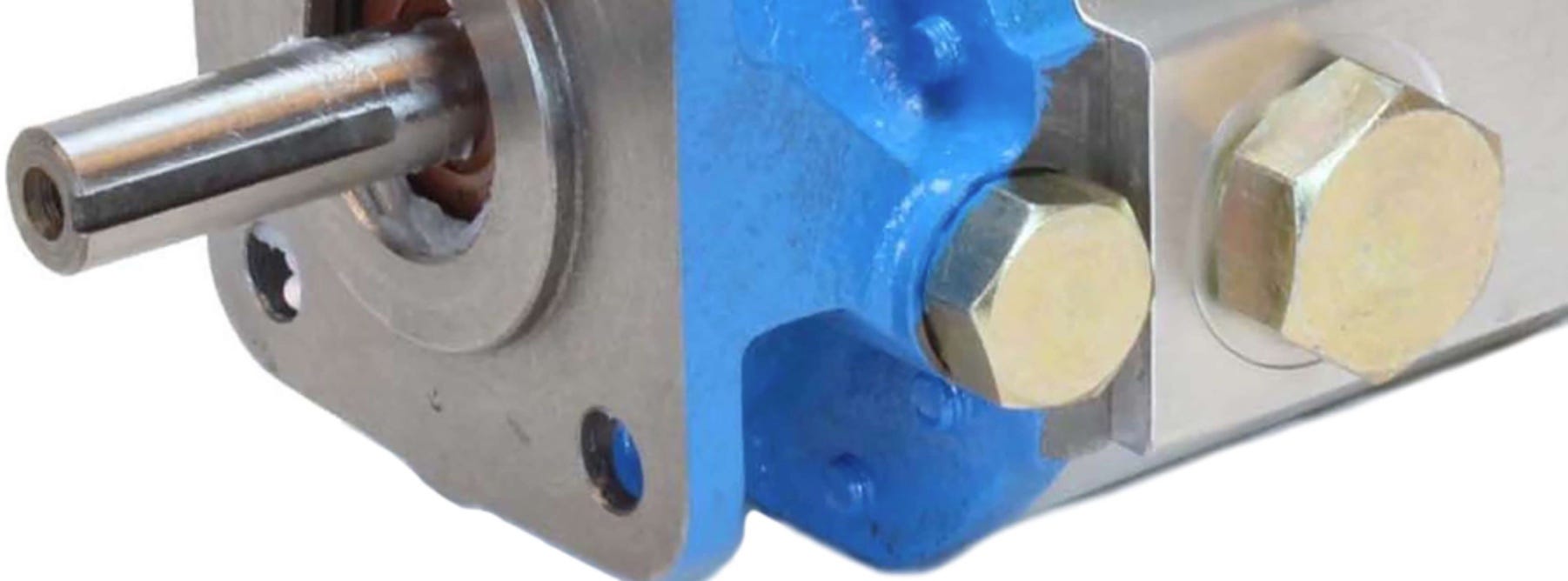

![[Hearth.com] Making an electric power pac for tractor splitter [Hearth.com] Making an electric power pac for tractor splitter](https://www.hearth.com/talk/data/attachments/319/319505-0be1707a82b530e153a59b55da44d2ba.jpg?hash=_dRWagf_ax)

![[Hearth.com] Making an electric power pac for tractor splitter [Hearth.com] Making an electric power pac for tractor splitter](https://www.hearth.com/talk/data/attachments/319/319506-0e6fe327bbd503887e68c49b29529632.jpg?hash=cP85zkCrEy)

![[Hearth.com] Making an electric power pac for tractor splitter [Hearth.com] Making an electric power pac for tractor splitter](https://www.hearth.com/talk/data/attachments/319/319505-0be1707a82b530e153a59b55da44d2ba.jpg?hash=_dRWagf_ax)

![[Hearth.com] Making an electric power pac for tractor splitter [Hearth.com] Making an electric power pac for tractor splitter](https://www.hearth.com/talk/data/attachments/319/319506-0e6fe327bbd503887e68c49b29529632.jpg?hash=cP85zkCrEy)

Thanks. Is your motor a totally enclosed fan cooled?I am no expert but I think the belt and pulley system may be difficult to guard and use safely. I run a 4x18 inch cylinder. forgot the shaft size, and 11gpm pump off a 2 hp ,220, 3450 rpm motor. The motor is a C face and connects to the pump directly through an adapter. It is not fast but there is very little that gives it difficulty. I would say that is the best way to go. If starting with a new ,or maybe better, a used motor stay with 3450 rpm. A five hp seems like it would be plenty for the 16 gpm pump

View attachment 319478 View attachment 319479

Those motors are well built to handle harsh conditions. mine will be inside all the time.I like the higher cycle time so would want a 13 gpm minumum pump. Any idea what your cycle time is on your set up?I have found a used Baldor motor though its more of a compressor type being open drip style. 3450 rpm in the tefc style are hard to find and out of my price range new. i can easily make up a safety shroud but there will be diffently more efficiency loss going thru those pulleys to run the pump at 3600 rpm.Thanks. Is your motor a totally enclosed fan cooled?

It is fan cooled

Thanks. Is your motor a totally enclosed fan cooled?

I don’t know the cycle time. It’s very comfortable. As I try to recollect how long a stroke might take I’m thinking it is likely I have a 20” cylinder not an 18.Those motors are well built to handle harsh conditions. mine will be inside all the time.I like the higher cycle time so would want a 13 gpm minumum pump. Any idea what your cycle time is on your set up?I have found a used Baldor motor though its more of a compressor type being open drip style. 3450 rpm in the tefc style are hard to find and out of my price range new. i can easily make up a safety shroud but there will be diffently more efficiency loss going thru those pulleys to run the pump at 3600 rpm.

![[Hearth.com] Making an electric power pac for tractor splitter [Hearth.com] Making an electric power pac for tractor splitter](https://www.hearth.com/talk/data/attachments/319/319508-e9dba953ab2221fab3982e76ffb17771.jpg?hash=QK5bBeB8F0)

Thanks for infoI don’t know the cycle time. It’s very comfortable. As I try to recollect how long a stroke might take I’m thinking it is likely I have a 20” cylinder not an 18.

View attachment 319481

brenndatomu

Minister of Fire

Speeding up with pulleys using that motor will not work...when you double the speed, you half the torque.Currently have a 5hp leeson TEFC motor @1750 RPM I'd like to use. I'd have to use a couple of right sized pulleys to run a 3600 16gpm 2 stage pump. Think this would work? Other option is to buy a 5hp compressor c face type motor rated at 20-23 amps and mount pump directly to motor. Is either option enough motor to run the pump or should I go to a 11 or 13 gpm pump. I did read somewhere of someone going to make one using a 5 hp 1750 motor running a 28 gpm pump but don't know if this would work. I do want a fast cycle time like I currently have with the splitter run off the tractor (about a 6-8 cycle time). Thanks

If you can find a used 220V 20+ amp compressor motor, that would work to pull a 16 GPM pump, which is what you'll want to get the cycle time you are after.

If you watch you can find used compressors with those 20+ amp 3500 RPM motors on them...not super common though, most are the "special" motors that are only 15-16 amps, even though they are rated at "5 HP"

One of those would still pull a 16 GPM pump though, just have to keep your hi/lo shift point pressure turned down, and high end relief pressure too...which really isn't that big of a deal, since most wood splits before even hitting those pressure points.

Ok great. I have found a used c face 5 hp Baldor 20 amp motor . Would it have no problem running a 16 gpm 2 stage pump? When that pump gears down to the lower gpm at higher pressure will that motor draw more than rated and possibly burn motor out over time? I could go down to a 13 gpm pump but would still like around that 9 cycle time but not sure if I can achieve that with the smaller pump.Speeding up with pulleys using that motor will not work...when you double the speed, you half the torque.

If you can find a used 220V 20+ amp compressor motor, that would work to pull a 16 GPM pump, which is what you'll want to get the cycle time you are after.

If you watch you can find used compressors with those 20+ amp 3500 RPM motors on them...not super common though, most are the "special" motors that are only 15-16 amps, even though they are rated at "5 HP"

One of those would still pull a 16 GPM pump though, just have to keep your hi/lo shift point pressure turned down, and high end relief pressure too...which really isn't that big of a deal, since most wood splits before even hitting those pressure points.

brenndatomu

Minister of Fire

It should be fine...you just need to mount a pressure gauge in the pump side of the control valve so you can set your pressures.Would it have no problem running a 16 gpm 2 stage pump? When that pump gears down to the lower gpm at higher pressure will that motor draw more than rated and possibly burn motor out over time? I could go down to a 13 gpm pump but would still like around that 9 cycle time but not sure if I can achieve that with the smaller pump.

And just to be clear, the motor will draw the highest amps right before it shifts to "low gear" (high pressure) so that's why its important to set the shift point pressure, to control your amps.

A 16 GPM pump should get you into the 6.5 second range (depending on if your lines and fittings are big enough to handle that much fluid...and your cylinder, I bet your 3.5" cylinder only has 3/8" holes (at the largest) even though the lines are probably 1/2") Also, what size is the ram rod? That affects the return stroke time too.

A 13 GPM pump, everything being equal, still gets you in the sub 8 second range.

All these numbers are based on the cylinder being a true 3.5" ID, 24" stroke, and a 2" ram/rod size...and lines/ports that are big enough to not restrict that much flow...which speaking of, with increased flow, especially with smaller lines and small 90* fittings, comes more heat buildup in the oil, and most splitters are woefully small on their oil capacity (should really have double the gallons that the pump is rated at...so a 16 GPM pump should ideally have a 32 gallon tank) but no splitters, short of a full blown commercial unit, have anywhere near that much oil on board...they just rely on the average person not using the unit long enough to get hot...that and they assume most people will split wood in cold weather...but the bottom line is that they just don't care about your machines reduced life due to elevated oil temps.

But log splitter builds can really suck you down the rabbit hole, so you just have to decide whats good enough, and let it be good enough, otherwise you it just ends up costing WAY more than you thought it would, and taking way more time too...I speak from experience, as I'm just finishing one myself.

The couple guys on here that advise starting with a large splitter (like north of 30 tons) with good specs, and then just putting a smaller cylinder on it, are absolutely right, that would definitely be the fastest/easiest/cheapest way to build a fast splitter!

By the way, here is a great resource for calculating things for a custom splitter build.

Log Splitter Hydraulic Cylinder Cycle Time and Speed Calculator

Wood Splitter Hydraulic Cylinder Cycle Time and Speed Calculator for Splitting Logs

logsplitterplans.com

The splitter is a 2 way hydraulic tractor mount made here in Canada. Splifire is the make and they have been making them for years. Its rated up to 12gpm flow rate and has the sweeping hydraulic lines with no 90s. The exact cylinder specs I'm not sure of but the lines do look like they are a little bigger than 1/2 ". I may just go to a 13gpm pump to be on the safe side. I have one other question to ask you. Another guy on the gear forum has made a few of these electric pumps as well. I mentioned that I have a 5hp TEFC motor ( much heavier made than the compressor style) but its only 1725 rpm. He said if he was to build another he'd use a 1725 rpm motor and put on a 3600 rpm higher gpm hydraulic 2 stage pump direct drive). For my motor it would be a 22 or 28 gpm hydraulic 2 stage pump ( they do make them but are almost double cost). With the slower rpm motor on the higher rpm pump it would basically cut the gpm in half but my concern would be if it still put out enough pressure( or would it be lower too because pump is at 1/2 speed) to keep me in that 18 tonne range . Plus not sure about amp draw on that pump with my motor. Thanks again for your time. My knowledge is limited in this area. Cost wise either would roughly be the same.It should be fine...you just need to mount a pressure gauge in the pump side of the control valve so you can set your pressures.

And just to be clear, the motor will draw the highest amps right before it shifts to "low gear" (high pressure) so that's why its important to set the shift point pressure, to control your amps.

A 16 GPM pump should get you into the 6.5 second range (depending on if your lines and fittings are big enough to handle that much fluid...and your cylinder, I bet your 3.5" cylinder only has 3/8" holes (at the largest) even though the lines are probably 1/2") Also, what size is the ram rod? That affects the return stroke time too.

A 13 GPM pump, everything being equal, still gets you in the sub 8 second range.

All these numbers are based on the cylinder being a true 3.5" ID, 24" stroke, and a 2" ram/rod size...and lines/ports that are big enough to not restrict that much flow...which speaking of, with increased flow, especially with smaller lines and small 90* fittings, comes more heat buildup in the oil, and most splitters are woefully small on their oil capacity (should really have double the gallons that the pump is rated at...so a 16 GPM pump should ideally have a 32 gallon tank) but no splitters, short of a full blown commercial unit, have anywhere near that much oil on board...they just rely on the average person not using the unit long enough to get hot...that and they assume most people will split wood in cold weather...but the bottom line is that they just don't care about your machines reduced life due to elevated oil temps.

But log splitter builds can really suck you down the rabbit hole, so you just have to decide whats good enough, and let it be good enough, otherwise you it just ends up costing WAY more than you thought it would, and taking way more time too...I speak from experience, as I'm just finishing one myself.

The couple guys on here that advise starting with a large splitter (like north of 30 tons) with good specs, and then just putting a smaller cylinder on it, are absolutely right, that would definitely be the fastest/easiest/cheapest way to build a fast splitter!

By the way, here is a great resource for calculating things for a custom splitter build.

Log Splitter Hydraulic Cylinder Cycle Time and Speed Calculator

Wood Splitter Hydraulic Cylinder Cycle Time and Speed Calculator for Splitting Logslogsplitterplans.com

brenndatomu

Minister of Fire

I'm not sure on this one...I really think you'd run into amp draw issues, but I'd have to think about this scenario a bit.I have one other question to ask you. Another guy on the gear forum has made a few of these electric pumps as well. I mentioned that I have a 5hp TEFC motor ( much heavier made than the compressor style) but its only 1725 rpm. He said if he was to build another he'd use a 1725 rpm motor and put on a 3600 rpm higher gpm hydraulic 2 stage pump direct drive). For my motor it would be a 22 or 28 gpm hydraulic 2 stage pump ( they do make them but are almost double cost). With the slower rpm motor on the higher rpm pump it would basically cut the gpm in half but my concern would be if it still put out enough pressure( or would it be lower too because pump is at 1/2 speed) to keep me in that 18 tonne range . Plus not sure about amp draw on that pump with my motor. Thanks again for your time. My knowledge is limited in this area. Cost wise either would roughly be the same.

I personally wouldn't risk it...you'll have headaches with adapting the larger pump I'd think...and you'd have to adapt the hoses too.

If you are going to use this in the barn mostly, I don't think using a compressor motor would be a big deal at all.

Rugged Made has both 13 and 16 GPM pumps for just over $100.

Hydraulic Pumps for Log Splitters | RuggedMade

Keep your hydraulics running smoothly with wood splitter hydraulic pumps. Designed for log splitters & other compatible equipment. Shop today!

Just a couple of points...

2 stage splitter pumps are not designed for side load. Belts and pulleys are a no-no unless you configure it like a jack shaft (pia).

Your 5hp 1750 rpm running a 16gpm 2 stage should have more than enough power and the speed with a 3.5 cylinder will be respectable even using your current hose config.

Edit: you will be pushing that motor to its limit trying to run 22gpm.

2 stage splitter pumps are not designed for side load. Belts and pulleys are a no-no unless you configure it like a jack shaft (pia).

Your 5hp 1750 rpm running a 16gpm 2 stage should have more than enough power and the speed with a 3.5 cylinder will be respectable even using your current hose config.

Edit: you will be pushing that motor to its limit trying to run 22gpm.

Yes but it would be too slow for me. Was going to use my 1725 rpm motor on a 22 gpm 3600 rpm 2 stage pump. The gpm would be cut in half using my slower motor on a higher rpm pump ( So in theory would be roughly same gpm as a 3600rpm motor driving a a 3600 16 gpm 2 stage pump) . I just didn't know if the would still put up enough pressure and other problems driving it with a slower rpm motor and if it would draw more amps when it switches to high pressure. I still want that 18 tonne range. Maybe i'm out to lunch on this one but just just trying to figure out the different possibilities . And I would fabricate a bracket so I could direct drive the pump.Just a couple of points...

2 stage splitter pumps are not designed for side load. Belts and pulleys are a no-no unless you configure it like a jack shaft (pia).

Your 5hp 1750 rpm running a 16gpm 2 stage should have more than enough power and the speed with a 3.5 cylinder will be respectable even using your current hose config.

Edit: you will be pushing that motor to its limit trying to run 22gpm.

ericm979

Feeling the Heat

Yes but it would be too slow for me. Was going to use my 1725 rpm motor on a 22 gpm 3600 rpm 2 stage pump. The gpm would be cut in half using my slower motor on a higher rpm pump ( So in theory would be roughly same gpm as a 3600rpm motor driving a a 3600 16 gpm 2 stage pump) . I just didn't know if the would still put up enough pressure and other problems driving it with a slower rpm motor and if it would draw more amps when it switches to high pressure. I still want that 18 tonne range. Maybe i'm out to lunch on this one but just just trying to figure out the different possibilities . And I would fabricate a bracket so I could direct drive the pump.

Pressure does not depend on flow, as long as there is some.

I'd think that a 3600 rpm 5hp motor would cost less than a 22gpm two stage pump.

There are on line calculators that will tell you the power required to pump at a given flow and pressure. The pump's data sheet should tell you the cut over pressure, the flow of the high pressure/low flow stage and the overall relief pressure. From those you can get the power reuirements.

brenndatomu

Minister of Fire

After thinking about this more, I don't believe this will work...your GPM will be "half" but the pumping rate will still be too much...as in its a larger pump, (so larger gears) therefore it will be moving more oil with each revolution...pressure wise it won't change, these are considered PD pumps, so if the motor/wiring is big enough, it will make the same pressure.The gpm would be cut in half using my slower motor on a higher rpm pump ( So in theory would be roughly same gpm as a 3600rpm motor driving a a 3600 16 gpm 2 stage pump)

They draw less amps in high pressure (low flow) mode...the big amp draw is when in low pressure/high flow mode, right before it shifts to high pressure/low flow mode.if it would draw more amps when it switches to high pressure

Last edited:

brenndatomu

Minister of Fire

That motor will cost twice what the pump will.I'd think that a 3600 rpm 5hp motor would cost less than a 22gpm two stage pump.

Yeah I posted a link for a "all things log splitter" calculator a few posts back...There are on line calculators that will tell you the power required to pump at a given flow and pressure.

Similar threads

- Replies

- 3

- Views

- 5K

- Replies

- 32

- Views

- 6K