I can't turn down the airflow on my 2008 Alderlea T5 enough. Door gasket seems good. Just put in new door glass and gasket since glass had cracked and glass gasket was leaking air. Thought that would solve my air flow problem. It made it better but still can't slow down the flow as much as when new. I've inspected things and don't see anything warped from overheating and the damper seems to be working right but I can't restrict the incoming air as much as I'd like to control the fire. When new I could shut damper far enough to slow the fire down to a simmer but now even shutting the damper down all the way I get more of a burn than I'd like. Makes me careful not to add much fuel at a time as afraid it might burn to fast and hot. Any ideas appreciated on how to deal with this.

Overburn problem

- Thread starter AltaVistaStove

- Start date

-

Active since 1995, Hearth.com is THE place on the internet for free information and advice about wood stoves, pellet stoves and other energy saving equipment.

We strive to provide opinions, articles, discussions and history related to Hearth Products and in a more general sense, energy issues.

We promote the EFFICIENT, RESPONSIBLE, CLEAN and SAFE use of all fuels, whether renewable or fossil.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Welcome. Do the dollar bill test on the door at multiple points and make sure the door glass gasket is sealing all the way around. Also, are the insulation blocks on either side of the baffle in good condition and touching up against the baffle? Has the baffle secondary tube gasket been replaced after cleaning?

Another thing that can change is the species of wood, its dryness and thickness. Some types of wood burn hotter and faster than otheres. Thicker splits will burn slower.

Is the stove being loaed N/S and tightly packed?

Another thing that can change is the species of wood, its dryness and thickness. Some types of wood burn hotter and faster than otheres. Thicker splits will burn slower.

Is the stove being loaed N/S and tightly packed?

Thanks for the reply! I just watched some UTube videos. Will be easy to do the dollar bill test. Will also try to take out the baffle to inspect. What would tell you that a new baffle is needed? Anyway this all gives me hope I can fix this stove and continue to use it!Welcome. Do the dollar bill test on the door at multiple points and make sure the door glass gasket is sealing all the way around. Also, are the insulation blocks on either side of the baffle in good condition and touching up against the baffle? Has the baffle secondary tube gasket been replaced after cleaning?

Another thing that can change is the species of wood, its dryness and thickness. Some types of wood burn hotter and faster than otheres. Thicker splits will burn slower.

Is the stove being loaed N/S and tightly packed?

It takes a lot of abuse, typically overfiring a lot, to wear out a PE baffle. A baffle will need to be replaced when

it no longer can direct secondary air properly. This usually shows up as a bad sag and rupture on the bottom side or front edge. Our T6 baffle is the same age as your stove and it is still in very good condition.

it no longer can direct secondary air properly. This usually shows up as a bad sag and rupture on the bottom side or front edge. Our T6 baffle is the same age as your stove and it is still in very good condition.

Pipe goes up about 3 feet above stove then 90 degrees and out through wall, then It's about 20 feet tall, from basement extending through main floor, attic and extending up out of roof.How tall is your chimney?

Was the fire controllable before the glass cracked and was replaced? Do you have any sooty areas around the glass?

Where are you located?

Where are you located?

It was more controllable so I think part of problem was the glass and old glass gasket was leaking air into the burn chamber. New glass and gasket helped some but did not solve the problem. I'm going to replace the door gasket also though I don't think that is the problem. Also plan to take the baffle out and look things over. Not any noticeable sooty areas around the glass. Glass itself stays pretty clean.Was the fire controllable before the glass cracked and was replaced? Do you have any sooty areas around the glass?

Where are you located?

Want to get this figured out. When I first got it it seemed to provide more heat and was more controllable flame and just not sure what happened. Baffle doesn't look too bad as far as I can see but will take it out and look more closely at it. I'm located in Rapid City, SD in the foothills of the Black Hills. I have started really looking at YouTube videos about this stove. Even after using it for 17 years I'm still learning things about it.

It’s possible your wood is dryer now than it used to be. I start turning my stove down as soon as the fire starts hitting the baffle regularly. Turn it down in small increments. The fire will die back and then rebuild as it adjusts.

For a proper door seal, be sure that the door gasket is the original PE OEM part. Substitutes tend to not seal as well and are leaky.

Thanks! I did just order and receive an OEM door gasket so I plan to install it before burning season. The one presently on the door is not OEM though I can't detect any major leaks. Decided to switch to original gasket just to make sure.For a proper door seal, be sure that the door gasket is the original PE OEM part. Substitutes tend to not seal as well and are leaky.

Itslay90

Minister of Fire

Where did you order it from ??Thanks! I did just order and receive an OEM door gasket so I plan to install it before burning season. The one presently on the door is not OEM though I can't detect any major leaks. Decided to switch to original gasket just to make sure.

I took the baffle out of my Pacific Energy Alderlea T-5 today. It was in pretty good shape, one hairline crack on the front. I blew compressed air through it to remove any soot/dust buildup inside. I did notice that there is NOT a baffle gasket installed. Not sure why. Can't remember for sure but think I took baffle out once about 10 years ago just to clean things up as far as soot and maybe baffle gasket was lost at that time. Seems like I saw on a youtube video that that gasket is rather important so I'll order a replacement. Maybe that has been part of my problem.

I suspect that is the issue. About 5 yrs ago, I tried two different non-OEM gaskets. Those gaskets easily passed the dollar bill test, but they still leaked air. The OEM gasket is double-layered, more like a gasket inside of a gasket. It seals better.Thanks! I did just order and receive an OEM door gasket so I plan to install it before burning season. The one presently on the door is not OEM though I can't detect any major leaks. Decided to switch to original gasket just to make sure.

I took the baffle out of my Pacific Energy Alderlea T-5 today. It was in pretty good shape, one hairline crack on the front. I blew compressed air through it to remove any soot/dust buildup inside. I did notice that there is NOT a baffle gasket installed. Not sure why. Can't remember for sure but think I took baffle out once about 10 years ago just to clean things up as far as soot and maybe baffle gasket was lost at that time. Seems like I saw on a youtube video that that gasket is rather impo

Went down to my local Pacific Energy dealer where I bought my stove to purchase a new baffle gasket and found out they had done out of business. Have been having difficulties finding this item online. Can anyone point me in the right direction or suggest an alternative to using the OEM baffle gasket?

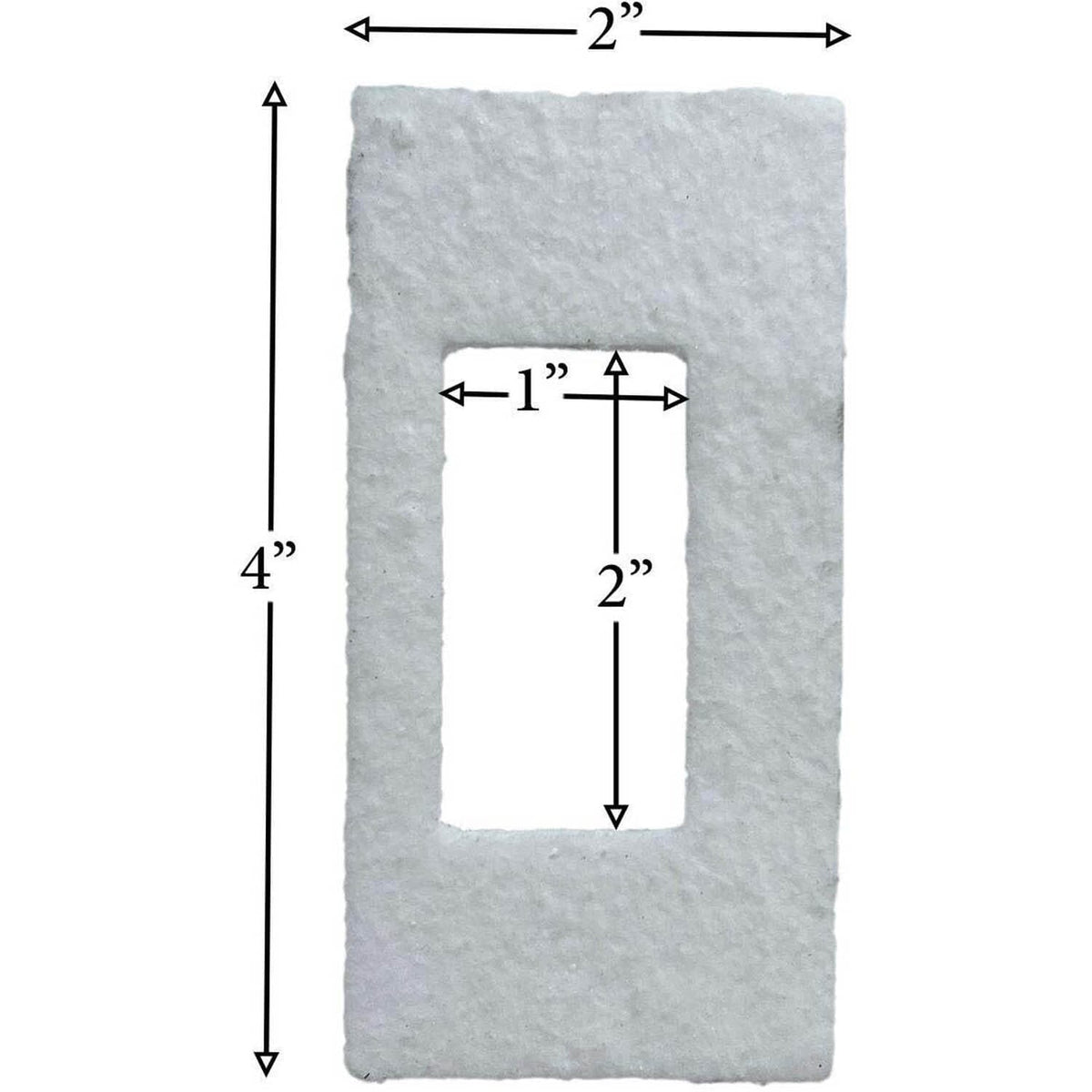

While I am a strong proponent for only using the OEM door gasket, the rear baffle gasket is a much less sensitive part. You could create your own out of 1/4" door gasket, or get a sheet of 1/8" or 1/4" ceramic gasket material and cut your own. I've been using a rope gasket for about 5 yrs now and am going to try cutting my own from a sheet of ceramic gasket this summer. To do this I'll probably make a cardboard template first. I'll be using something like this material.

If you want to try making a rope gasket, Hogwildz documented the process years ago.

Amazon.com: Rifatrio 4 Pcs High Temperature Gasket Paper DIY Ceramic Fiber Insulation Wood Stove Gasket for Pellet Stove, Kiln, Boiler, Forge, RV Furnace Gaskets 10" x 7" x 1/8" Thick : Home & Kitchen

Amazon.com: Rifatrio 4 Pcs High Temperature Gasket Paper DIY Ceramic Fiber Insulation Wood Stove Gasket for Pellet Stove, Kiln, Boiler, Forge, RV Furnace Gaskets 10" x 7" x 1/8" Thick : Home & Kitchen

www.amazon.com

If you want to try making a rope gasket, Hogwildz documented the process years ago.

Did my cleaning this past Sunday. Even took off the surround, side grilles, top shelf & ash shelf.

Painted the air fins on top black and the front inner corners of the casing black. Spent some time on her, now its humming along and I am enjoying.

First off, about screened chimney caps. Here are photos of mine last cleaned New Years last year, burned until almost up to May last year and started up evening fires last week. Burning most of today & yesterday as it has been chilly here. So much for the build up theories. I say it comes down to the wood you burn, how dry and how it is burnt!

Cap...

Painted the air fins on top black and the front inner corners of the casing black. Spent some time on her, now its humming along and I am enjoying.

First off, about screened chimney caps. Here are photos of mine last cleaned New Years last year, burned until almost up to May last year and started up evening fires last week. Burning most of today & yesterday as it has been chilly here. So much for the build up theories. I say it comes down to the wood you burn, how dry and how it is burnt!

Cap...

- Hogwildz

- Replies: 58

- Forum: The Hearth Room - Wood Stoves and Fireplaces

Pacific Energy PCP 199 Baffle Gasket Vista & Super Series: 80000365Default Title

Replacement Baffle Gasket For The Vista & Super Series

Woody5506

Minister of Fire

Typically the baffle gasket should be replaced any time you drop the baffle for cleaning. I don't think I did mine last year because it was still fairly intact. If you're careful with how you remove the baffle then the gasket may stay intact and be fine to use for another season but I'd imagine after 10 years that thing was long gone even without removing the baffle. I used to just buy about 5 at a time from the dealer so I had them on hand, but I did happen to see some on Amazon yesterday which I believe were OEM.Went down to my local Pacific Energy dealer where I bought my stove to purchase a new baffle gasket and found out they had done out of business. Have been having difficulties finding this item online. Can anyone point me in the right direction or suggest an alternative to using the OEM baffle gasket?

sixer

Member

+1 for making your own baffle gasket. I have some 1/8" flat gasket material from a local shop. I just cut a piece long enough to cover the rectangular opening on the baffle and then use a blade to cut the opening, using the opening on the baffle itself as a guide (basically cut along the inside edge). This year I folded the gasket material in half before cutting to make it thicker (for no particular reason). A whole roll of that gasket material was like 10-15 bucks. I didn't measure it, but it's probably enough for about 20+ gaskets! I replace it every time I clean the chimney (1-2 times/yr).While I am a strong proponent for only using the OEM door gasket, the rear baffle gasket is a much less sensitive part. You could create your own out of 1/4" door gasket, or get a sheet of 1/8" or 1/4" ceramic gasket material and cut your own. I've been using a rope gasket for about 5 yrs now and am going to try cutting my own from a sheet of ceramic gasket this summer. To do this I'll probably make a cardboard template first. I'll be using something like this material.

Amazon.com: Rifatrio 4 Pcs High Temperature Gasket Paper DIY Ceramic Fiber Insulation Wood Stove Gasket for Pellet Stove, Kiln, Boiler, Forge, RV Furnace Gaskets 10" x 7" x 1/8" Thick : Home & Kitchen

Amazon.com: Rifatrio 4 Pcs High Temperature Gasket Paper DIY Ceramic Fiber Insulation Wood Stove Gasket for Pellet Stove, Kiln, Boiler, Forge, RV Furnace Gaskets 10" x 7" x 1/8" Thick : Home & Kitchenwww.amazon.com

If you want to try making a rope gasket, Hogwildz documented the process years ago.

Did my cleaning this past Sunday. Even took off the surround, side grilles, top shelf & ash shelf.

Painted the air fins on top black and the front inner corners of the casing black. Spent some time on her, now its humming along and I am enjoying.

First off, about screened chimney caps. Here are photos of mine last cleaned New Years last year, burned until almost up to May last year and started up evening fires last week. Burning most of today & yesterday as it has been chilly here. So much for the build up theories. I say it comes down to the wood you burn, how dry and how it is burnt!

Cap...

- Hogwildz

- Replies: 58

- Forum: The Hearth Room - Wood Stoves and Fireplaces

Similar threads

- Replies

- 9

- Views

- 249

- Replies

- 5

- Views

- 488

- Replies

- 5

- Views

- 365

- Replies

- 37

- Views

- 1K

- Replies

- 9

- Views

- 2K