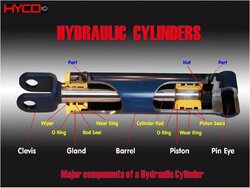

Hello All! My brother and I recently acquired a homemade log splitter that was a non-working project. We got it up and running and we have a hydraulic leak where the ram piston comes out of the housing. Is this an easy fix or would we better off pulling the whole ram off and dropping it off at a hydraulics shop? We are both pretty good mechanics so we're not afraid to do it ourselves, but don't want to get in over our heads since we aren't hydraulic experts.

Can anyone tell us what all is involved in fixing a leak like this?

Can anyone tell us what all is involved in fixing a leak like this?

(and I like the challenge).

(and I like the challenge).