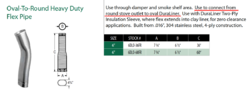

Looking at the catalog, is this the adapter you are looking at?

As an alternative, if you have a good supplier maybe try the Durablack stove adapter (crimped on male end and snap lock on female end) to see how it connects with the male end of the round Duraliner?

edit, we cross posted. I saw the angled adapters too.

As an alternative, if you have a good supplier maybe try the Durablack stove adapter (crimped on male end and snap lock on female end) to see how it connects with the male end of the round Duraliner?

edit, we cross posted. I saw the angled adapters too.