Hello

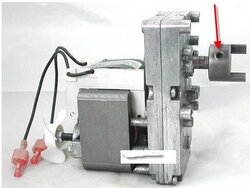

I am working on a top feed pellet stove that has a frozen allen head set screw that holds the auger motor shaft on the auger. See pic below of similar set screw.

So any tips on freeing the screw without breaking of course?

My friend suggested this:

1. Using a stainless steel bristle brush to brush the sides of the screw that stick out of the collar.

http://www.sears.com/shc/s/p_10153_12605_00910044000P?prdNo=2&blockNo=2&blockType=G2

See small brush in $2.00 kit > http://www.harborfreight.com/6-piece-detail-brush-set-93610.html

2. Spray penetrating spray such as PB Blaster to seep in. Let soak for a couple hours.

See > http://www.amazon.com/Blaster-16-PB-Penetrating-Catalyst-oz/dp/B000I2079E

3. If needed heat collar with Map Gas torch.

http://www.homedepot.com/h_d1/N-5yc...d=10053&langId=-1&keyword=torch&storeId=10051

4. Instead if a simple 5/32" allen wrench use a 5/32" allen socket for 3/8" ratchet drive for more torque.

Also banging the screw and collar. The vibration may help to loosen the set screw.

Any other suggestions? -- click on pic to enlarge and see red arrow below.

I am working on a top feed pellet stove that has a frozen allen head set screw that holds the auger motor shaft on the auger. See pic below of similar set screw.

So any tips on freeing the screw without breaking of course?

My friend suggested this:

1. Using a stainless steel bristle brush to brush the sides of the screw that stick out of the collar.

http://www.sears.com/shc/s/p_10153_12605_00910044000P?prdNo=2&blockNo=2&blockType=G2

See small brush in $2.00 kit > http://www.harborfreight.com/6-piece-detail-brush-set-93610.html

2. Spray penetrating spray such as PB Blaster to seep in. Let soak for a couple hours.

See > http://www.amazon.com/Blaster-16-PB-Penetrating-Catalyst-oz/dp/B000I2079E

3. If needed heat collar with Map Gas torch.

http://www.homedepot.com/h_d1/N-5yc...d=10053&langId=-1&keyword=torch&storeId=10051

4. Instead if a simple 5/32" allen wrench use a 5/32" allen socket for 3/8" ratchet drive for more torque.

Also banging the screw and collar. The vibration may help to loosen the set screw.

Any other suggestions? -- click on pic to enlarge and see red arrow below.