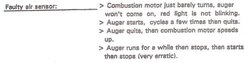

I own a used Austroflamm Integra that will go through normal start up cycle and feed pellets intermittantly for approximately 2 minutes(red light comes on) the combustion motor runs, but then the auger motor will not come on again at all after that. The combustion motor continues to run and after about 7 minutes after start up, the convection fan will turn on and you can adjust the fan speed. But, no more pellets.

I have replaced both the high and low limit switches and replaced the air flow sensor. I have also sent the user control panel, wiring harness, air sensor, and the motherboard in for testing and repair to the Austroflamm specialist pelletstoverepair.com and he is at a loss and assures me that my electronics are working normally.

The stove is clean inside and out and the door is well-sealed. Any suggestions as I don't know what to do next and am at the point of giving up on this stove.

I have replaced both the high and low limit switches and replaced the air flow sensor. I have also sent the user control panel, wiring harness, air sensor, and the motherboard in for testing and repair to the Austroflamm specialist pelletstoverepair.com and he is at a loss and assures me that my electronics are working normally.

The stove is clean inside and out and the door is well-sealed. Any suggestions as I don't know what to do next and am at the point of giving up on this stove.