I have the HI300 insert and am trying to get the secondary burn. We followed the instructions on the video's, the wood is dry at about 15-20, don't know the kind of wood. I get the temps up to 747 degrees on the glass and 278-327 degrees on the shelf just above the door, I am using an infrared thermometer, checked- its accurate. Are these temps high enough? The wood burns down fast, gone to coal in about 2 hours, but it is burning off the black creosote off the glass.

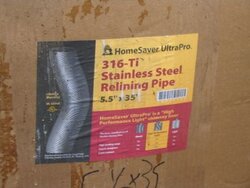

My insert is in an interior masonry wall , using a 32' or 33' SS liner. Not insulated. Any suggestions?

My insert is in an interior masonry wall , using a 32' or 33' SS liner. Not insulated. Any suggestions?