Isn't the dealer taking the 3100? They have to atleast pull the ul label offThe 2450 is for sale. I think the 3100 I'm just going to toss in the junk. Not even sure what a fair price on that unit would be. 3100 does have an extra blower that I never used.

Regency l3100 Cracks

- Thread starter davidmsem

- Start date

-

Active since 1995, Hearth.com is THE place on the internet for free information and advice about wood stoves, pellet stoves and other energy saving equipment.

We strive to provide opinions, articles, discussions and history related to Hearth Products and in a more general sense, energy issues.

We promote the EFFICIENT, RESPONSIBLE, CLEAN and SAFE use of all fuels, whether renewable or fossil.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Dealer's not taking the 3100.Isn't the dealer taking the 3100? They have to atleast pull the ul label off

I think they have enough of these with cracks in the exact same location as mine. Reduces the cost to pull and ship.Hmmmm that is odd.

The dealer is required to take the unit pull the tag send it to regency and destroy the unit. They don't want the actual stove back. But they don't want damaged units out there they replaced already.I think they have enough of these with cracks in the exact same location as mine. Reduces the cost to pull and ship.

Not this dealer......The dealer is required to take the unit pull the tag send it to regency and destroy the unit. They don't want the actual stove back. But they don't want damaged units out there they replaced already.

That is regencies requirements when they issue a replacement under warranty. It is clearly spelled out in the dealers warranty info.Not this dealer......

Maybe he doesn't care about the requirements? Wouldn't surprise me.....That is regencies requirements when they issue a replacement under warranty. It is clearly spelled out in the dealers warranty info.

If he doesn't return the tag he will be billed for the replacement stove.Maybe he doesn't care about the requirements? Wouldn't surprise me.....

I have him the tag.If he doesn't return the tag he will be billed for the replacement stove.

Oh then they were just lazy and didn't want to take the stove. That's differentI have him the tag.

MongoMongoson

Feeling the Heat

One thing I don't see in your pictures is the brass tube that is your vacuum pickup. That has to be on the stove side of the damper, and should be near the center of the flue. If you have the vacuum pickup above the damper, it won't tell you the draft your stove is experiencing. Maybe you do have it below the damper for measurement and it just was not installed when you took the pics.

Oh then they were just lazy and didn't want to take

Thank you again for the use of the meter. Here is a picture where you can see the brass tube inserted below the damper. I find the measurements at all distances the probe is inserted into the pipe to be the same, but default to the center as you instructed.One thing I don't see in your pictures is the brass tube that is your vacuum pickup. That has to be on the stove side of the damper, and should be near the center of the flue. If you have the vacuum pickup above the damper, it won't tell you the draft your stove is experiencing. Maybe you do have it below the damper for measurement and it just was not installed when you took the pics.

The hole for inserting the brass tube is just below the damper.

john26

Minister of Fire

EbS-P

Minister of Fire

I have been thinking about the location of the magnahelic brass tube. I think it’s position will affect the reading. Remember we are measuring less than1/4” of water column. The pressure gradient (above to below the damper )must be continuous. I just blew gently across the tube of mine (not into it) and the needle moved .05”. Blow like you are blowing out a candle and it’s .15-20”. My point is that near the damper there are some regions of higher velocity and if the end of the tube is in that region it will read higher.Thank you again for the use of the meter. Here is a picture where you can see the brass tube inserted below the damper. I find the measurements at all distances the probe is inserted into the pipe to be the same, but default to the center as you instructed.

The hole for inserting the brass tube is just below the damper.

View attachment 293617

Can we generalize how much draft reduction we would expect to see using a single damper?

Can we move the brass tube to the stove intake and see home much of a difference the damper has at that location?

Just some thoughts. Personally I might not install the damper until after I pass inspection. It would be passed woth surround removed, No???

I got a used magnahelic 0-.25” wc for 35$ shipped of eBay. It’s not worth rushing at this point of the season IMO. You have time.

Evan

GREAT pic and reference. Thank youHere's a few pics of my damper that I run on my PE, I run it fully closed. I do not have a manometer hooked up yet so no numbers. Also PE series D insert with custom surround I believe 1/116th sheet metal with damper handle accessible through the face.

...

!

!I have been thinking about the location of the magnahelic brass tube. I think it’s position will affect the reading. Remember we are measuring less than1/4” of water column. The pressure gradient (above to below the damper )must be continuous. I just blew gently across the tube of mine (not into it) and the needle moved .05”. Blow like you are blowing out a candle and it’s .15-20”. My point is that near the damper there are some regions of higher velocity and if the end of the tube is in that region it will read higher.

Can we generalize how much draft reduction we would expect to see using a single damper?

Can we move the brass tube to the stove intake and see home much of a difference the damper has at that location?

Just some thoughts. Personally I might not install the damper until after I pass inspection. It would be passed woth surround removed, No???

I got a used magnahelic 0-.25” wc for 35$ shipped of eBay. It’s not worth rushing at this point of the season IMO. You have time.

Evan

Thank you for the post.

With respect to "Can we generalize how much draft reduction we would expect to see using a single damper? " I honestly don't know.

With respect to "Can we move the brass tube to the stove intake and see home much of a difference the damper has at that location?" I can tell you that I have had it above the damper, below the damper, near the edge of the duct, near the center of the duct. NO NOTICIBLE change at all.

I suspect some states might not approve of an install with a damper in place. This is odd because the unit will pollute more, and have problems with overheating which might also be a fire hazard.

Yup, I'm lucky when I noticed this.

Stay tuned Evan, I'm needing the help

!

!A GLIMMER OF HOPE

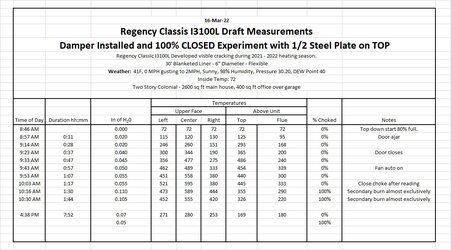

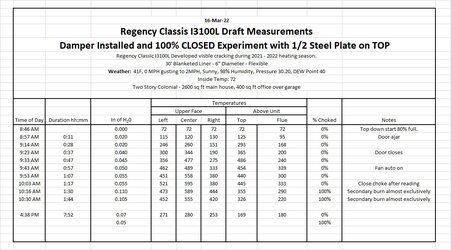

I do not weld or rivet, but I had a 5" round piece of 1/2" thick steel that I placed ABOVE my damper. You can see in the picture the holes are certainly more blocked.

I ran another experiment today and the results are a pretty decent shift in draft in a favorable direction. The fire seemed to come up slower and I had MORE control over the fire even when it was reaching cruising temps. I could not take reading after 10:30am, but the insert appeared to be reaching a plateau. I can run a longer experiment tomorrow if needed, but I think this is the first REAL EVIDENCE I have that a damper, modified with it's holes CLOSED, is the way to go if you want to operate the unit in accord with the manufacturer's specifications.

Any thoughts and reflections from @bholler or other experts would be extremely helpful !

!

I do not weld or rivet, but I had a 5" round piece of 1/2" thick steel that I placed ABOVE my damper. You can see in the picture the holes are certainly more blocked.

I ran another experiment today and the results are a pretty decent shift in draft in a favorable direction. The fire seemed to come up slower and I had MORE control over the fire even when it was reaching cruising temps. I could not take reading after 10:30am, but the insert appeared to be reaching a plateau. I can run a longer experiment tomorrow if needed, but I think this is the first REAL EVIDENCE I have that a damper, modified with it's holes CLOSED, is the way to go if you want to operate the unit in accord with the manufacturer's specifications.

Any thoughts and reflections from @bholler or other experts would be extremely helpful

!

!

Last edited:

One thing to realize is that even though you aren't dropping the draft as much as you or I would like you are still reducing the volume and velocity of the exhaust. That will change how it runs allot. I would still try covering the holes to get the draft down but it may work ok now

Thank you. Heating season is winding down and I can stagger through a couple of weeks with the Regency 3100. But I know for the next installation for the replacement unit what I need to do. I'm reading that some State codes do not allow tinkering with the exhaust but they also have rules and regulations about exhaust EPA limits. So you can't have both so it's very confusing what to do. Plus if you let it run you may over fire which can be another issue in your home.One thing to realize is that even though you aren't dropping the draft as much as you or I would like you are still reducing the volume and velocity of the exhaust. That will change how it runs allot. I would still try covering the holes to get the draft down but it may work ok now

And I covered the holes as best I could with the plate on top of the damper. It would slow the velocity etc. I don't rivet could have drill holes in attached it but I have enough data I think to see the trend. That was the purpose of all of this to see what needed to get done.

You have all proven to me that a damper is needed and it needs to have its holes plugged as ridiculous as that seems at first, to have the unit run in accord with the manufacturer's specifications.

I personally believe the industry is grossly negligent. They do what the EPA says and they stop. That's what happens when government gets involved I guess. Specifications for draft chimney heights all of these limitations that manufacturers know are hidden and very few people I think get to understand them or even ask about them. This is very unfortunate in my opinion. Transparency should be the rule especially we're fire is involved literally.

It is technically against code because it is not specified by the manufacturer. That being said installing a stove on a chimney that has excessive draft is also not installing as specified so that could be considered a code violation as well.Thank you. Heating season is winding down and I can stagger through a couple of weeks with the Regency 3100. But I know for the next installation for the replacement unit what I need to do. I'm reading that some State codes do not allow tinkering with the exhaust but they also have rules and regulations about exhaust EPA limits. So you can't have both so it's very confusing what to do. Plus if you let it run you may over fire which can be another issue in your home.

To be honest most inspectors won't notice it at all.

Overdraft is not defined in the instruction manual for any of these devices that I've looked at so far. So the industry is very clever. They could accuse you of over firing but they won't give you specifications in their installation instructions. This is a clever play by the industry.It is technically against code because it is not specified by the manufacturer. That being said installing a stove on a chimney that has excessive draft is also not installing as specified so that could be considered a code violation as well.

To be honest most inspectors won't notice it at a

It is in the tech manuals. As I said early in this it is your dealers faultOverdraft is not defined in the instruction manual for any of these devices that I've looked at so far. So the industry is very clever. They could accuse you of over firing but they won't give you specifications in their installation instructions. This is a clever play by the industry.

It is in the tech manuals. As I said early in this it is your dealers fa

Are these tech manuals published? It's brutal dealing with some of these places they don't even pick up the phone like Pacific Energy. Hard to get good information. As far as the previous unit failing it's water over the dam. Poor dealer, poor installation, overdrafting insert. Happy the house didn't burn down and glad I got 7 years out of it.It is in the tech manuals. As I said early in this it is your dealers fault

If the tech manual needs to be abided by it should be published and available for consumers and installers to follow.

DuaeGuttae

Minister of Fire

A GLIMMER OF HOPE

I do not weld or rivet, but I had a 5" round piece of 1/2" thick steel that I placed ABOVE my damper. You and see in the picture the holes are certainly more blocked.

I ran another experiment today and the results are a pretty decent shift in draft in a favorable direction. The fire seemed to come up slower and I had MORE control over the fire even when it was reaching cruising temps. I could not take reading after 10:30am, but the insert appeared to be reaching a plateau. I can run a longer experiment tomorrow if needed, but I think this is the first REAL EVIDENCE I have that a damper, modified with it's holes CLOSED, is the way to go if you want to operate the unit in accord with the manufacturer's specifications.

Any thoughts and reflections from @bholler or other experts would be extremely helpful!

View attachment 293635

View attachment 293637 View attachment 293638

Hurray!

Similar threads

- Replies

- 10

- Views

- 2K

- Replies

- 14

- Views

- 3K

- Replies

- 5

- Views

- 1K