kennyp2339

Minister of Fire

Flow from the stove to the chimney is your direction. Some cold chimneys have a reverse draft (especially if the install is in the basement) since cold air sinks, so you'll feel a little cold air drain when the stove is not in use, depending on how strong this is will determine your cold starting procedures.Thanks for the info! I used all non combustible material behind the stove all the way to the wall block which has no insulation in between the blocks, I think I'm good on clearance. I do like the idea of keeping better draft since my chimney is not enclosed in the structure.

If I use the two 45s, won't this pitch down toward the stove or would I still need to do this for the short span off the thimble?

Installing the double wall with the markings of the air flow, currently, I'm getting some backdrafting with lots of cold air coming down the chimney.. is that the direction or?

Some members will lite a few crumpled pieces of news paper to warm the flu before loading the stove, others have used a hair dryer, torch, even a work lite w/ 100w rough service bulb, I myself don't need any of it since its minimal I just lite a fire and walk away.

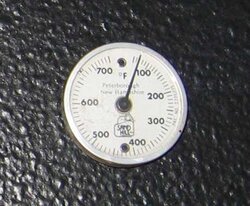

Remember to do break in fires to cure your paint and drive the moisture out of the fire brick, (3) small fires is all it takes, first small fire of kindling, let stove cool, 2nd larger fire of kindling and a few smaller splits, let cool off then 3rd fire is your final break in fire, fully loaded keeping temps at your cruise level (600 deg stove top)