Just looking at the spec sheet for Durock NexGen at https://www.usg.com/content/dam/USG...ck-next-gen-cement-board-datasheet-en-can.pdf

Avoid exposure to sustained temperatures exceeding 93°C(200°F).

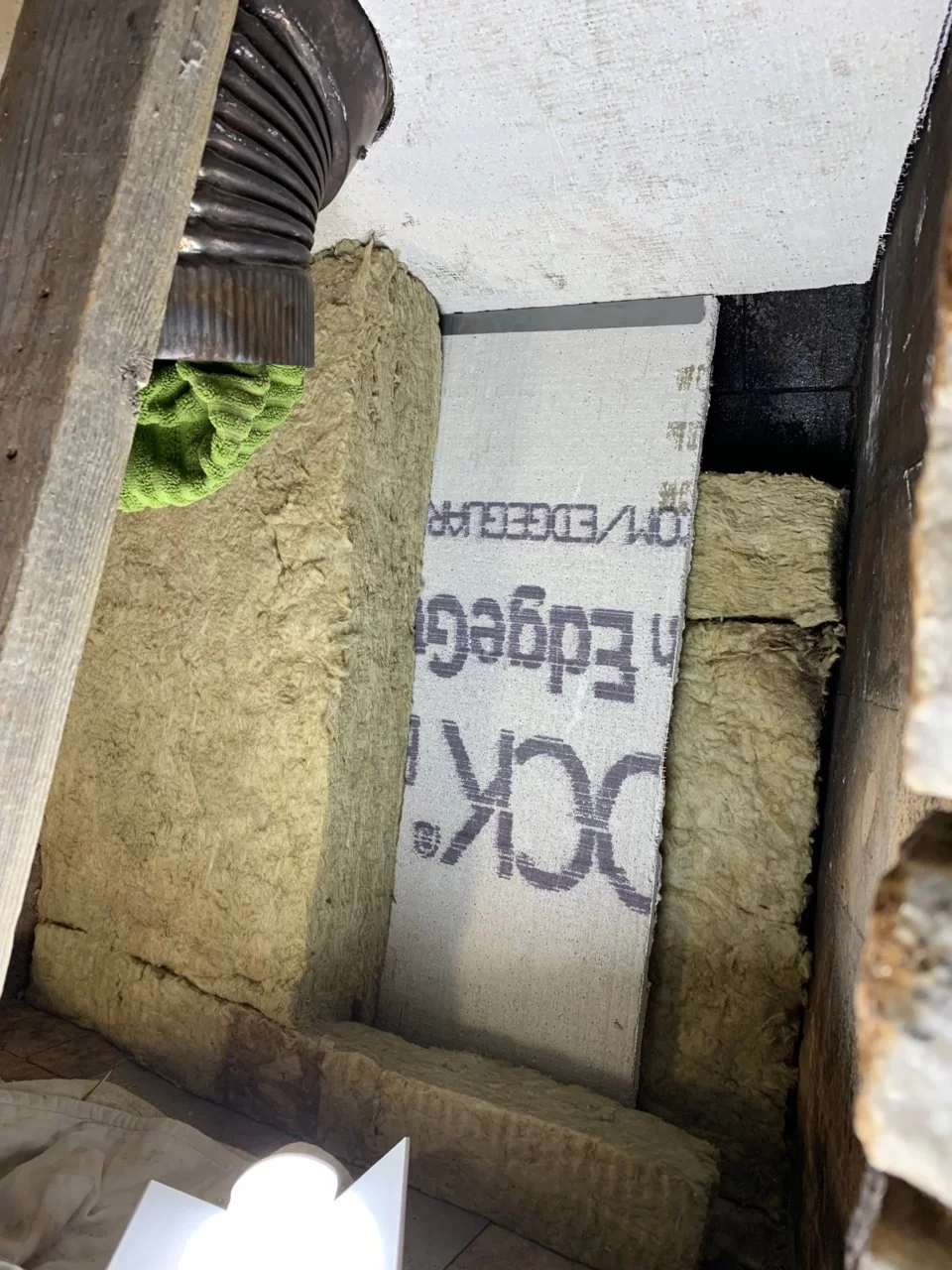

Hmm, wonder how warm it is where my pipe goes up through it?

Durock discussion

![[Hearth.com] Finally got around to insulating my fireplace [Hearth.com] Finally got around to insulating my fireplace](https://www.hearth.com/talk/data/attachments/238/238063-130e812d47209b0806af69a4bdd034bf.jpg?hash=pcGO1vQL8e)

![[Hearth.com] Finally got around to insulating my fireplace [Hearth.com] Finally got around to insulating my fireplace](https://www.hearth.com/talk/data/attachments/238/238064-2558c4bce24c93f0e9bdc13e2b8bc59b.jpg?hash=P4NobnpjP2)

![[Hearth.com] Finally got around to insulating my fireplace [Hearth.com] Finally got around to insulating my fireplace](https://www.hearth.com/talk/data/attachments/238/238065-29e613661df12040b6b09457fcb689d1.jpg?hash=fWdkOr79on)

![[Hearth.com] Finally got around to insulating my fireplace [Hearth.com] Finally got around to insulating my fireplace](https://www.hearth.com/talk/data/attachments/238/238066-22c3844b08ed838d039fbbfaa219df82.jpg?hash=f7hlefiY9V)

![[Hearth.com] Finally got around to insulating my fireplace [Hearth.com] Finally got around to insulating my fireplace](https://www.hearth.com/talk/data/attachments/238/238067-a2385293f1a34c12166211e8be8d874e.jpg?hash=7ZDyXCs_qg)

![[Hearth.com] Finally got around to insulating my fireplace [Hearth.com] Finally got around to insulating my fireplace](https://www.hearth.com/talk/data/attachments/238/238068-205b503750db1bb91c9738fb8ed2287c.jpg?hash=nAqT15Bjqh)

![[Hearth.com] Finally got around to insulating my fireplace [Hearth.com] Finally got around to insulating my fireplace](https://www.hearth.com/talk/data/attachments/238/238075-9c157c3d8deb0599c253364eea4e9977.jpg?hash=DN8RKcsgUV)

![[Hearth.com] Finally got around to insulating my fireplace [Hearth.com] Finally got around to insulating my fireplace](https://www.hearth.com/talk/data/attachments/238/238076-dca0c7326557a69961cca44a9670729d.jpg?hash=WA_66lCg80)

![[Hearth.com] Finally got around to insulating my fireplace [Hearth.com] Finally got around to insulating my fireplace](https://www.hearth.com/talk/data/attachments/238/238634-71f72b19fe3b93d929adca6efe1f5a7a.jpg?hash=vHlrxbbP0N)

![[Hearth.com] Finally got around to insulating my fireplace [Hearth.com] Finally got around to insulating my fireplace](https://www.hearth.com/talk/data/attachments/238/238635-62162aac309d5a87c17ea2c332609211.jpg?hash=Ixdor_ki0b)