Dear friends,

I have a Lange 6302 wood burning stove that I just bought used from someone.

It is cast iron with enamel coating. I think it is beautiful.

It looks similar to this one that someone already posted in the picture gallery:

Lange 6302

I have a few questions.

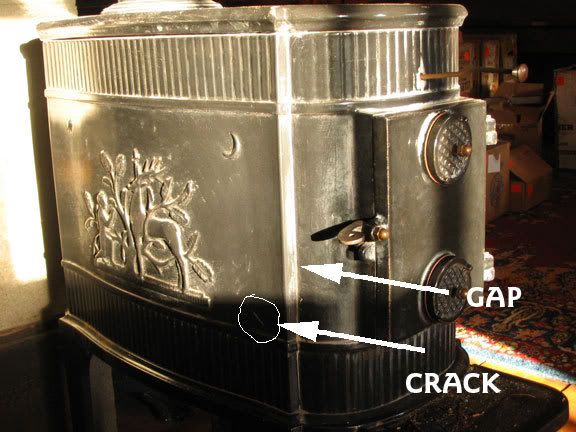

1) The stove is made from separate metal panels that are fitted together and there are very slight gaps between the panels that get wider or tighter as the stove heats up and expands or cools down. Sometimes I can see the faint glow of the fire through the gaps.

There isn't any apparent leaking of smoke into our living space.

a) Are these gaps normal or should I be concerned?

b) Will the gaps affect the performance of the stove?

c) Should I use some kind of furnace cement to try and seal the joints?

2) There is a small hairline crack on the left side panel about 2 inches long.

See the photo below:

a) Should I be concerned about this?

b) Should I try and stop any further cracking by using any cement on the inside? If so, would you recommend using High Temp Silicone Cement or some kind of furnace cement?

c) Will this affect the resale value of the stove?

3) Do you think $550 is a reasonable amount to pay for this stove?

4) Does anyone know what the date of this stove might be?

Thanks much!

I have a Lange 6302 wood burning stove that I just bought used from someone.

It is cast iron with enamel coating. I think it is beautiful.

It looks similar to this one that someone already posted in the picture gallery:

Lange 6302

I have a few questions.

1) The stove is made from separate metal panels that are fitted together and there are very slight gaps between the panels that get wider or tighter as the stove heats up and expands or cools down. Sometimes I can see the faint glow of the fire through the gaps.

There isn't any apparent leaking of smoke into our living space.

a) Are these gaps normal or should I be concerned?

b) Will the gaps affect the performance of the stove?

c) Should I use some kind of furnace cement to try and seal the joints?

2) There is a small hairline crack on the left side panel about 2 inches long.

See the photo below:

a) Should I be concerned about this?

b) Should I try and stop any further cracking by using any cement on the inside? If so, would you recommend using High Temp Silicone Cement or some kind of furnace cement?

c) Will this affect the resale value of the stove?

3) Do you think $550 is a reasonable amount to pay for this stove?

4) Does anyone know what the date of this stove might be?

Thanks much!