Hi and thanks in advance for any insights and ideas shared here!

We had a PelPro pellet stove installed in a corner of our living room. This was a new installation - no pellet or wood burning stove had ever existed before. Link to manual: https://downloads.hearthnhome.com/i...ET_FS_PPC90_TSC90_INSTALL_OWNERS_7093_600.pdf

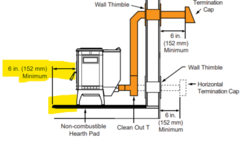

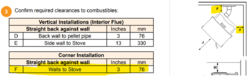

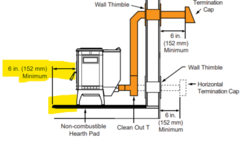

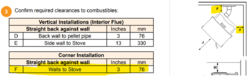

PelPro says the back corners of the stove need to be at least 3" away from the walls. The stove can be piped horizontally out of the wall and that's what the installer did.

As you can see in the photos I've uploaded, looking at the front of the stove the left rear corner is about 16" away from one wall, and the right corner is about 14" away from the other wall. This means there is less than the suggested 6" of hearth in front of the stove. It also means the stove feels like it's sitting in the middle of our living room. Apologies - that's an exaggeration; I'm aggravated by this install.

Our goal is to get the stove as close to 3" from each wall as we can so that it's centered on the hearth, tucked into the corner and we have 6" (or more) of hearth at the front of the stove.

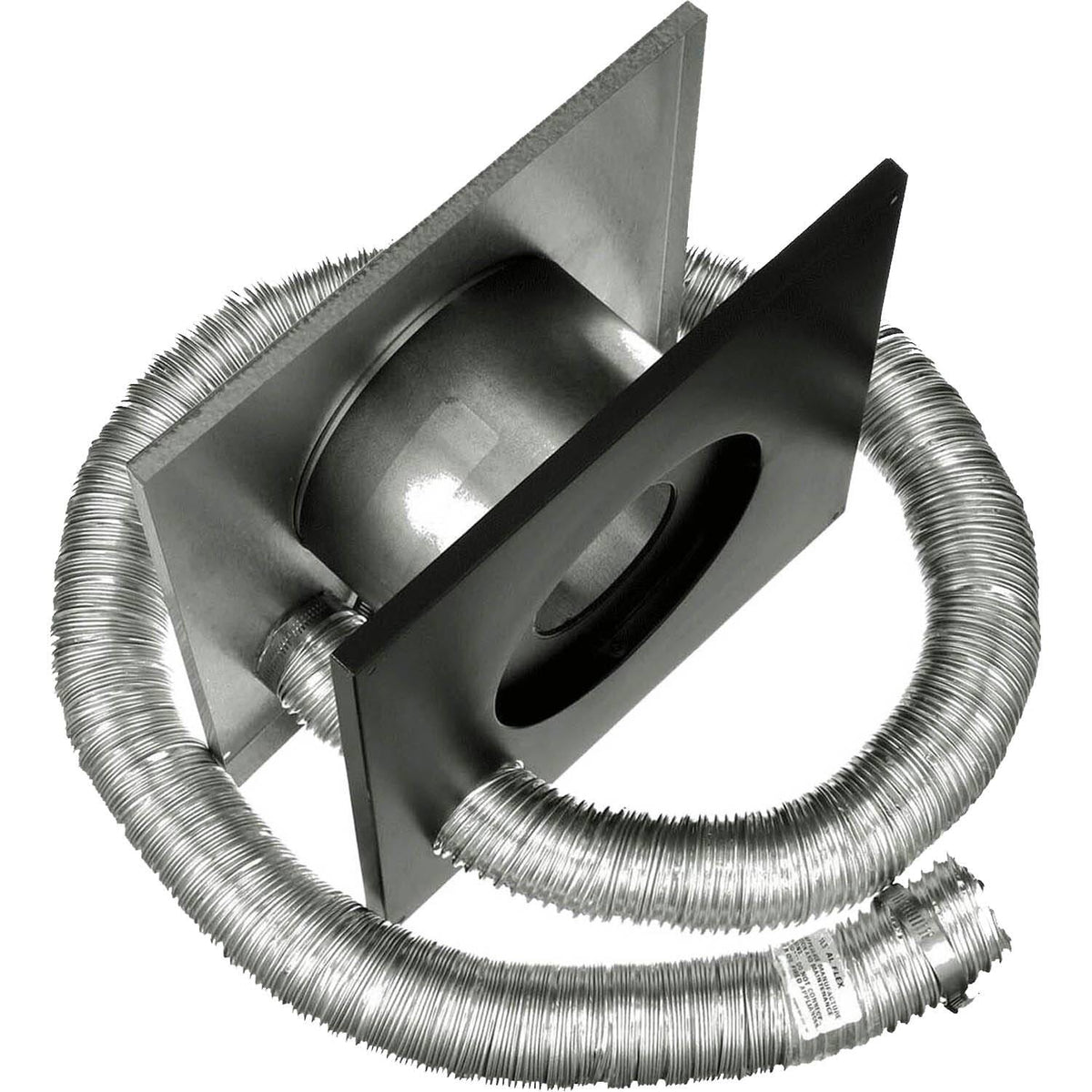

How can we get this thing closer to the back corner? If we swap in a 6" pipe in place of the 12" pipe that comes out of the wall and connects to the 90-degree pipe that connects to the clean-out T, could we push the stove back about 6"? Or would we need to add a second 90-degree pipe so that our pipe run from the wall would be 6" pipe to 90-degree pipe to 90-degree pipe to clean-out T?

Really appreciate any help thinking this through! Thank you!

We had a PelPro pellet stove installed in a corner of our living room. This was a new installation - no pellet or wood burning stove had ever existed before. Link to manual: https://downloads.hearthnhome.com/i...ET_FS_PPC90_TSC90_INSTALL_OWNERS_7093_600.pdf

PelPro says the back corners of the stove need to be at least 3" away from the walls. The stove can be piped horizontally out of the wall and that's what the installer did.

As you can see in the photos I've uploaded, looking at the front of the stove the left rear corner is about 16" away from one wall, and the right corner is about 14" away from the other wall. This means there is less than the suggested 6" of hearth in front of the stove. It also means the stove feels like it's sitting in the middle of our living room. Apologies - that's an exaggeration; I'm aggravated by this install.

Our goal is to get the stove as close to 3" from each wall as we can so that it's centered on the hearth, tucked into the corner and we have 6" (or more) of hearth at the front of the stove.

How can we get this thing closer to the back corner? If we swap in a 6" pipe in place of the 12" pipe that comes out of the wall and connects to the 90-degree pipe that connects to the clean-out T, could we push the stove back about 6"? Or would we need to add a second 90-degree pipe so that our pipe run from the wall would be 6" pipe to 90-degree pipe to 90-degree pipe to clean-out T?

Really appreciate any help thinking this through! Thank you!